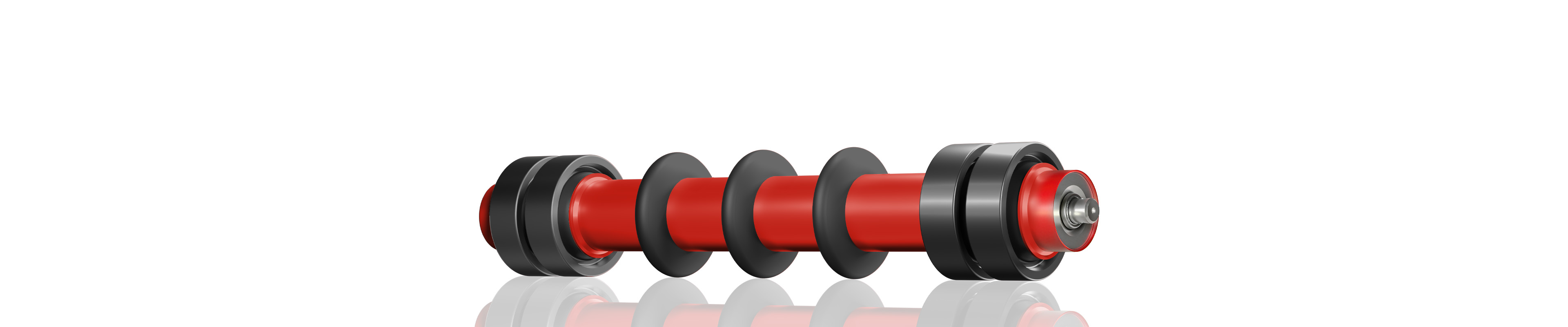

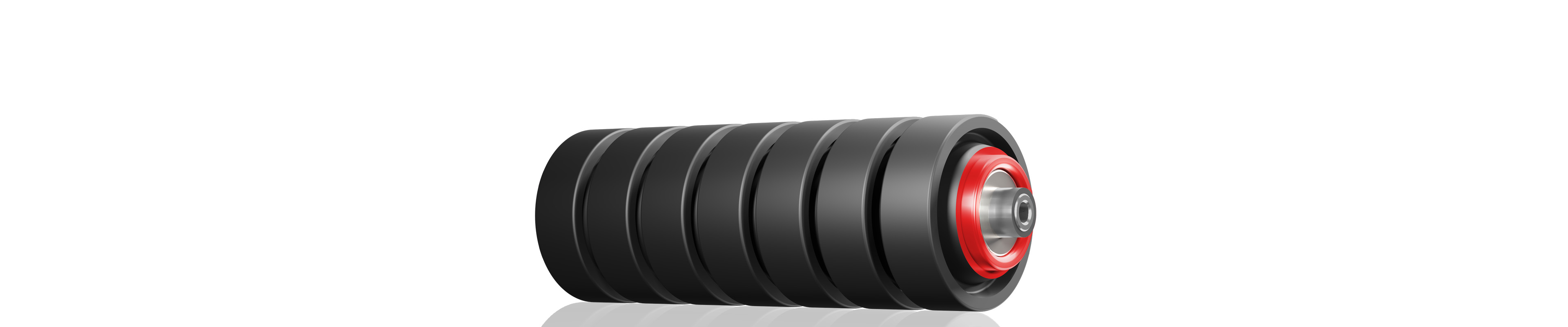

- Self-Cleaning Design: Prevents material build-up, particularly in the belt centre.

- Smooth Belt Return: Promotes steady belt movement with minimal friction.

- Durable Construction: Made with robust steel and high-quality bearings for long service life.

- Low Maintenance: Designed to reduce cleaning frequency and maintenance time.

- Enhanced Efficiency: Improves belt tracking, reduces drag, and prevents premature wear.

Common Industries That Use This Product

Cement, Aggregate, and Industrial Manufacturing

In cement and aggregate plants, conveyors face heavy contamination from fine dust, cement powder, and crushed stone particles. Rulmeca Return Rollers are engineered to solve this issue by preventing central material build-up that can cause uneven wear and belt misalignment. Their solid construction and precision-engineered design promote smooth return motion and minimal vibration. This helps maintain efficiency across production lines and extends the service life of belts in environments where dust and residue are unavoidable.

Agriculture and Fertilizer Processing

Power Generation and Biomass Plants

Mining and Quarrying Operations

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor