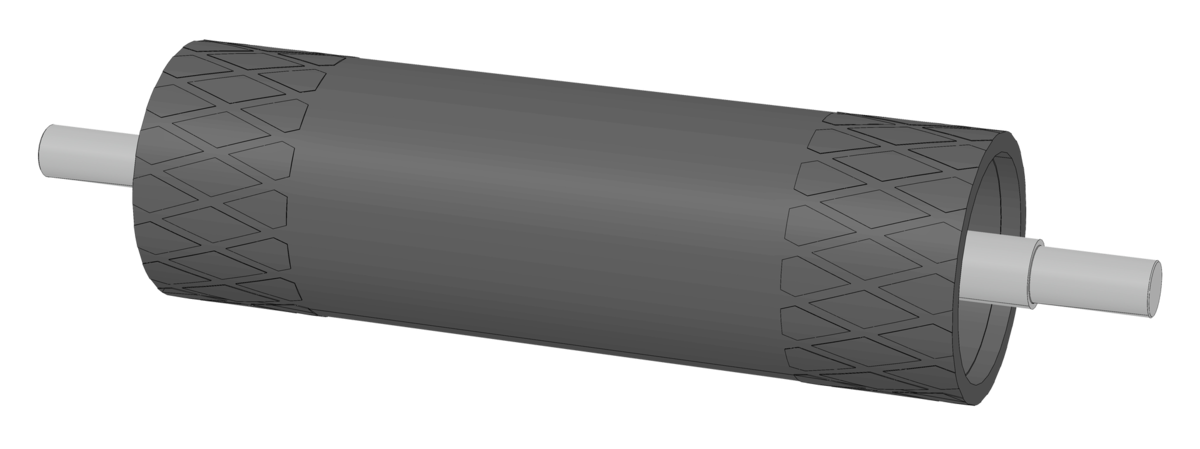

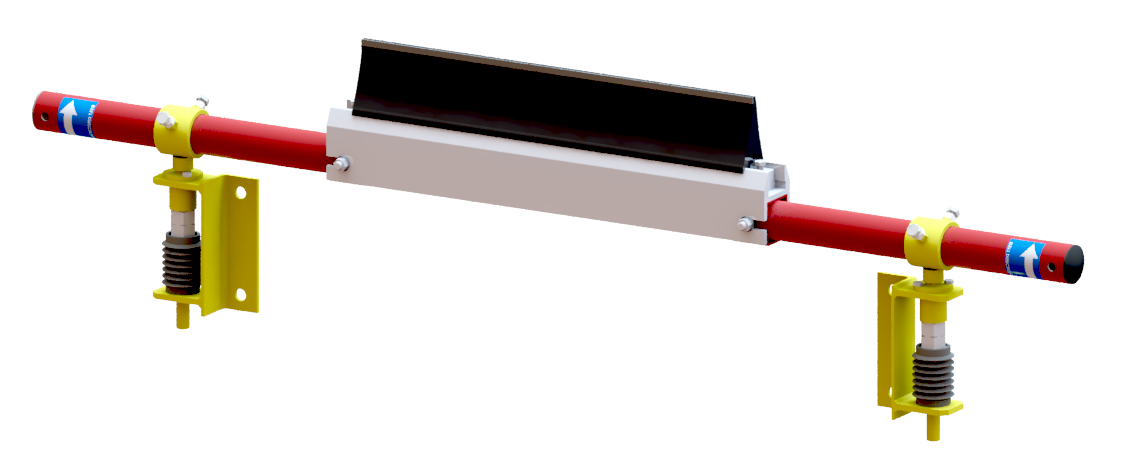

Built to ensure the highest level of conveyor cleanliness, the Jimway Torsion-Spring Secondary Cleaner is installed just after the head pulley to capture and remove remaining fines or sticky residues from the belt surface. Suitable for belt widths from 600 mm to 2000 mm (24″–78″) and speeds up to 4 m/s, this cleaner provides consistent, even pressure through its torsion-spring system, maintaining blade contact across the full belt width.

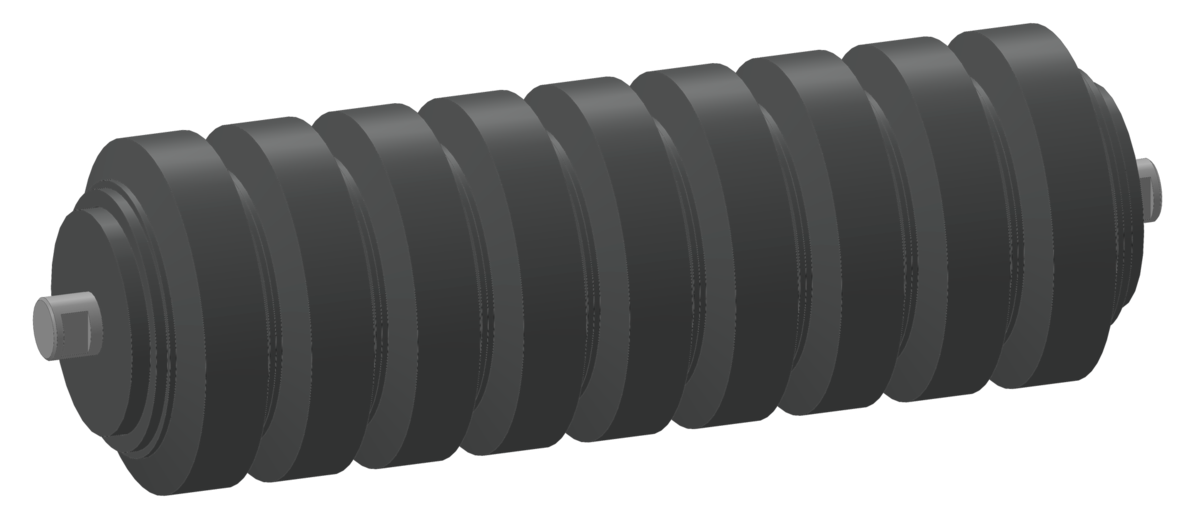

The torsion element absorbs vibration and noise while self-adjusting to belt surface changes or splices, ensuring steady cleaning performance without damaging the belt. Available with PU blades (SRUS) for general materials and tungsten carbide blades (SRTS/SRJS) for abrasive or heavy-duty environments, it offers flexibility for a wide range of industries. Designed for simplicity and economy, it’s easy to install, inspect, and maintain — reducing downtime and keeping your conveyors operating at peak efficiency.

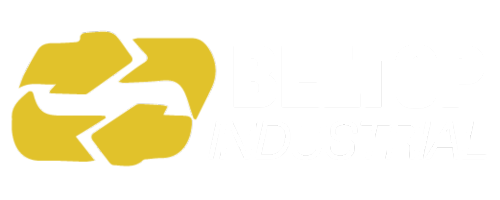

The Jimway Torsion-Spring Secondary Cleaner is designed for one-directional belts, supporting widths from 600 to 2000 mm and belt speeds up to 4 m/s. Blade options include durable polyurethane or tungsten carbide for various material-handling applications.

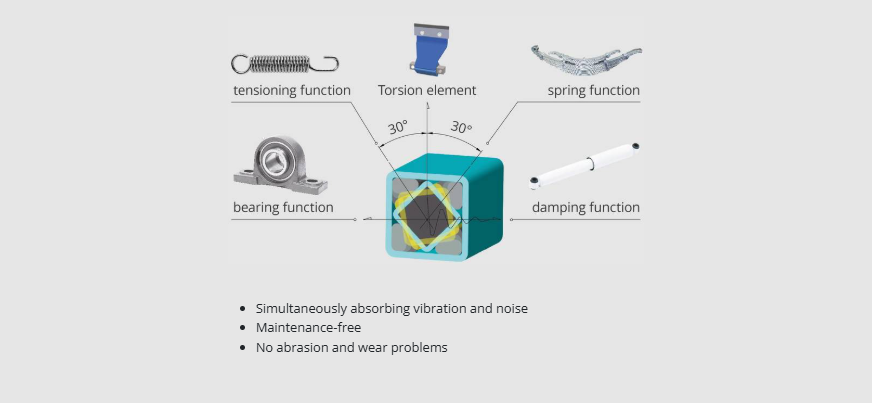

Excellent Elasticity Torsion Element

- Absorbs vibration and noise for smoother operation and reduced wear.

- Maintains consistent blade-to-belt contact for thorough cleaning.

- Self-adjusting mechanism compensates for belt irregularities and splices.

- Belt-friendly design prevents surface damage and extends belt lifespan.

- High-performance cleaning for both light and heavy-duty environments.

Easy to Install and Maintain

- Simple structure ensures quick installation and adjustment.

- Economical, low-maintenance design reduces downtime and service costs.

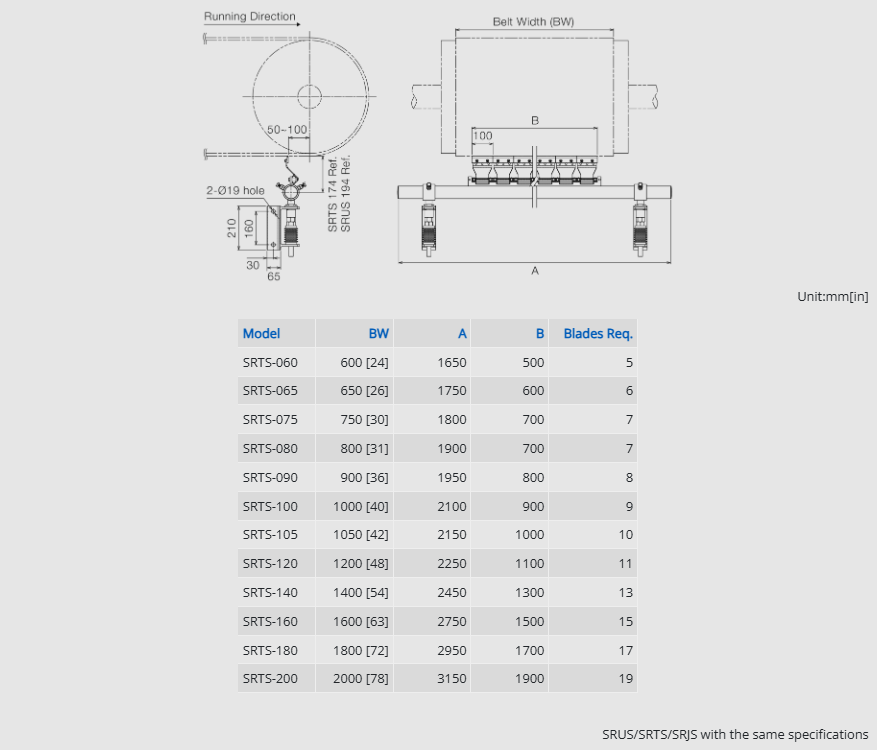

Specifications

Common Industries That Use This Product

Paper and Pulp Conveying Systems

In paper manufacturing and pulp processing, sticky residues and moisture can adhere to conveyor belts, leading to tracking and contamination issues. The Jimway Torsion-Spring Secondary Cleaner removes these fine materials efficiently, keeping the belt dry and clean. Its torsion system absorbs vibration, ensuring quiet operation and smooth cleaning; making it ideal for maintaining continuous production in high-moisture environments.

Cement and Aggregate Processing

Waste Recycling and Sorting Facilities

Food Grain and Feed Production

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor