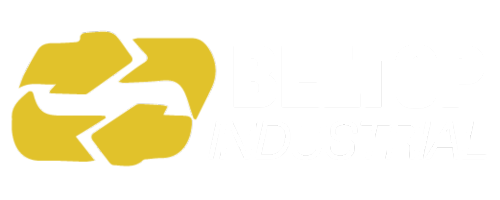

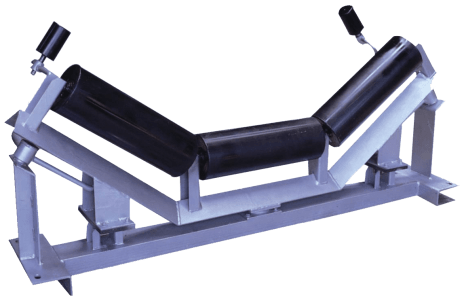

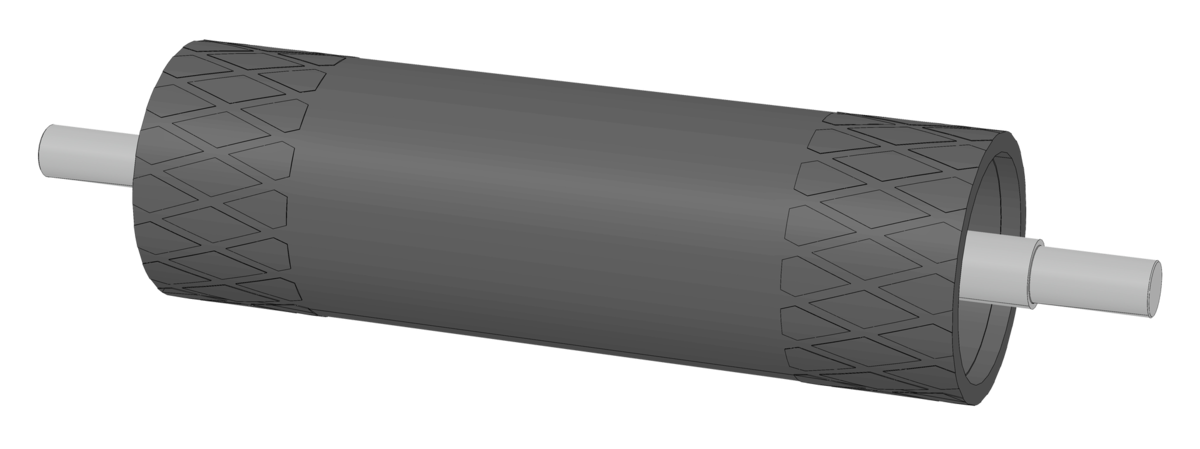

The JIMWAY Steel Roller is built for demanding conveyor systems where reliability, load capacity, and smooth operation are critical. Manufactured from high-grade steel tubing, each roller is precision-machined and balanced to ensure low noise, minimal vibration, and long-lasting performance.

Its robust structure and high-quality bearings provide excellent resistance to impact and wear, making it ideal for bulk handling, mining, quarrying, and industrial conveyor operations. With options for standard or custom dimensions, JIMWAY Steel Rollers deliver consistent belt support, reduced energy consumption, and low maintenance over years of continuous use.

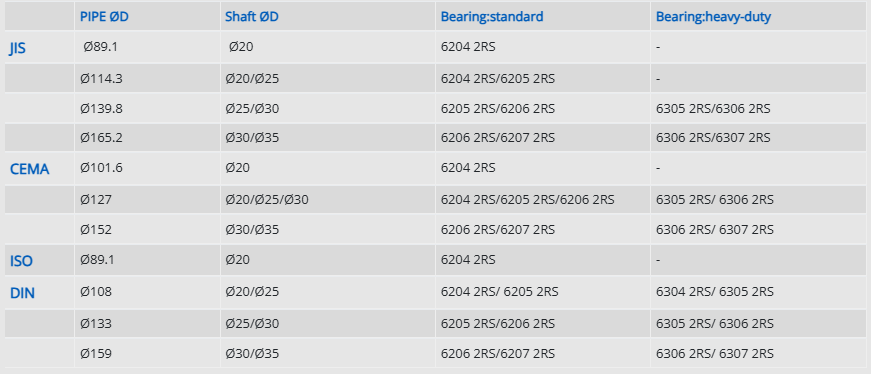

- Built to International Standards: Manufactured to meet JIS, CEMA, DIN, or ISO specifications, with customization available to fit any conveyor design or system requirement.

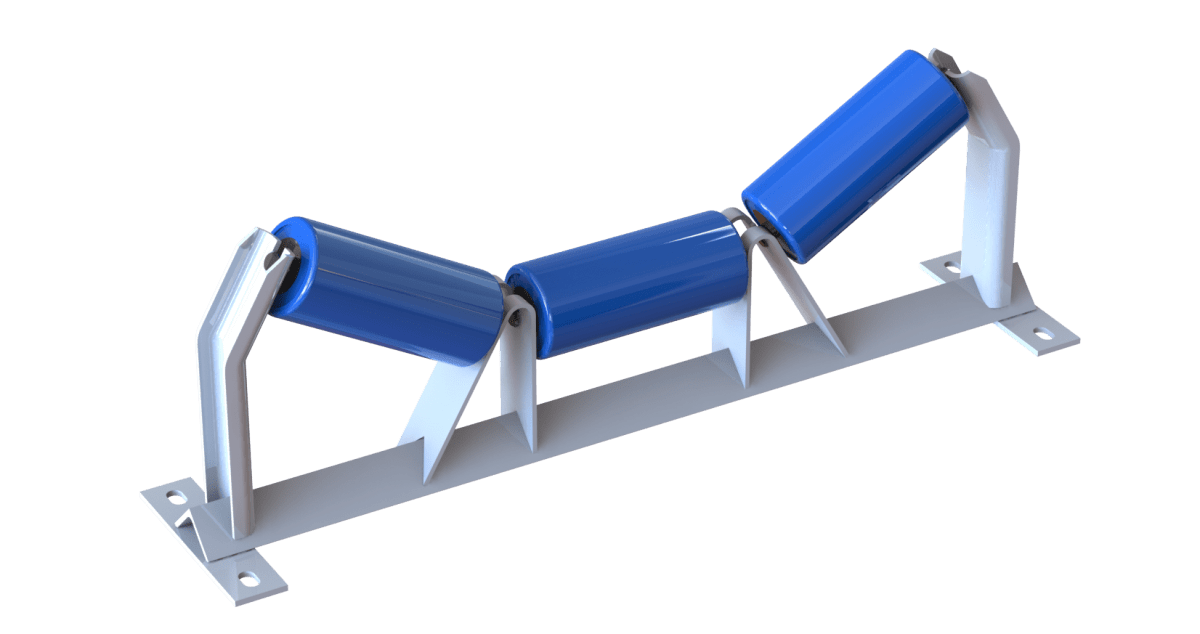

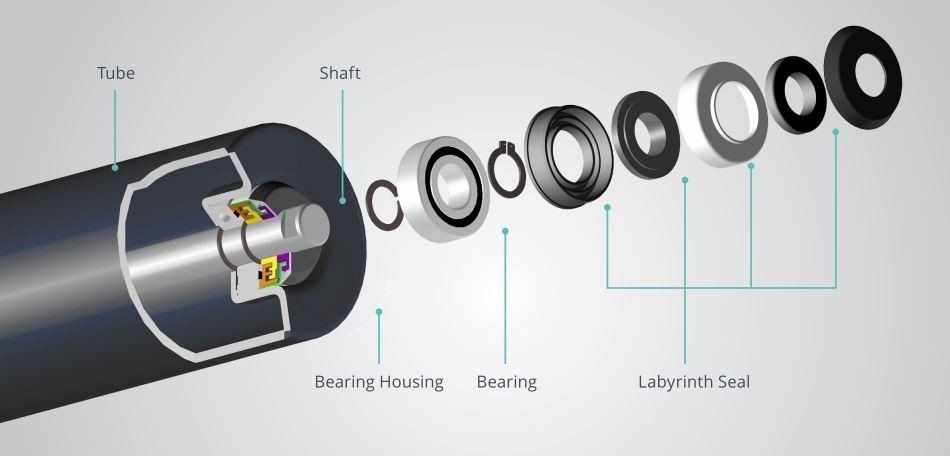

- Precision Bearings: Equipped with 2RS deep groove ball bearings (6204–6308) from premium brands such as NTN, SKF, FAG, and C&U. These bearings minimize friction, control temperature rise, and ensure smooth, long-lasting performance.

- Customizable Dimensions: Available in pipe outer diameters from Ø89.1 mm to Ø159 mm and shaft diameters from Ø20 mm to Ø35 mm, adaptable for different load and speed requirements.

- CNC-Machined Shaft: Each shaft is CNC precision-machined to JIS h7 tolerance, ensuring perfect alignment and minimal vibration during operation.

- High-Quality Bearing Housing: Bearing housings are CNC machined with JIS N7 seat tolerance, providing a precise fit that supports stable rotation and reduces bearing stress.

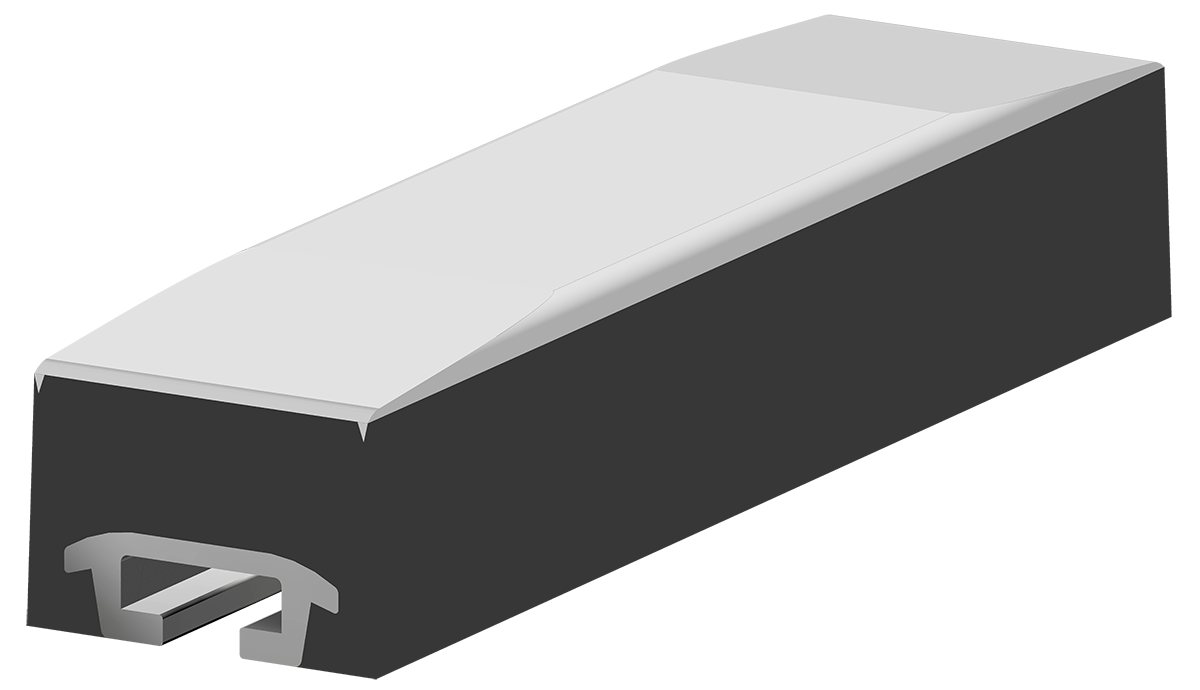

- Advanced Labyrinth Seal Design:

- Grease-filled labyrinth system offers superior protection against dust, water, and contaminants.

- Designed for excellent compressibility and resilience, maintaining effective sealing over time.

- Operates reliably across a wide temperature range, reducing maintenance needs in harsh environments.

- Premium Grease: Uses high-grade lubricants designed for two operating temperature ranges (-20°C to +65°C and -40°C to +65°C) to ensure consistent performance and power savings.

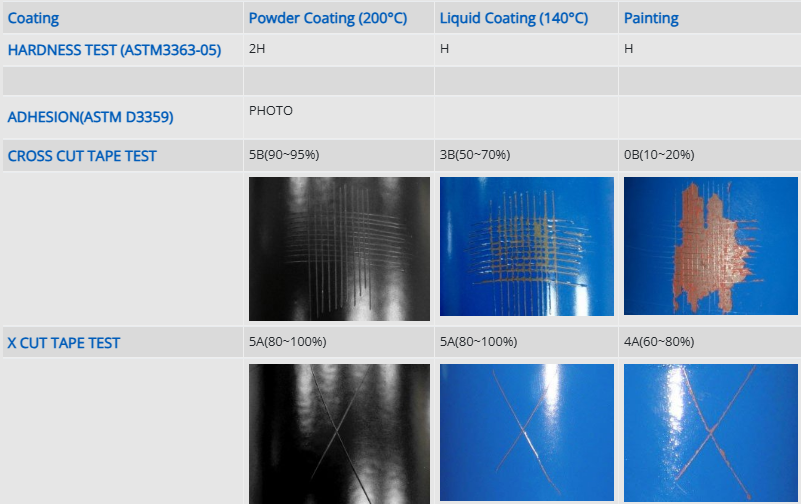

- Durable Powder Coating:

- Applied in thicknesses of 50–300 μm per cycle for superior impact and abrasion resistance.

- The process includes rust removal and degreasing before coating, improving surface adhesion and extending roller lifespan.

- Environmentally friendly and resistant to wear during handling and operation.

Specification

Coating and Testing

Common Industries That Use This Product

Mining & Quarrying

Steel & Metal Processing

Cement & Aggregate Production

Power Generation

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor