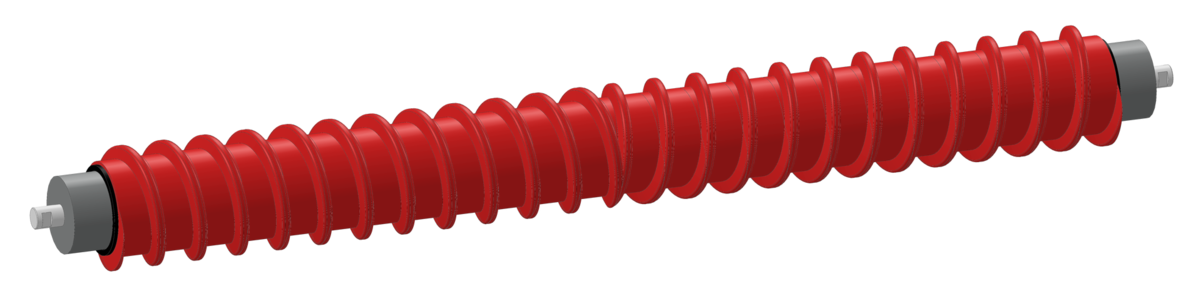

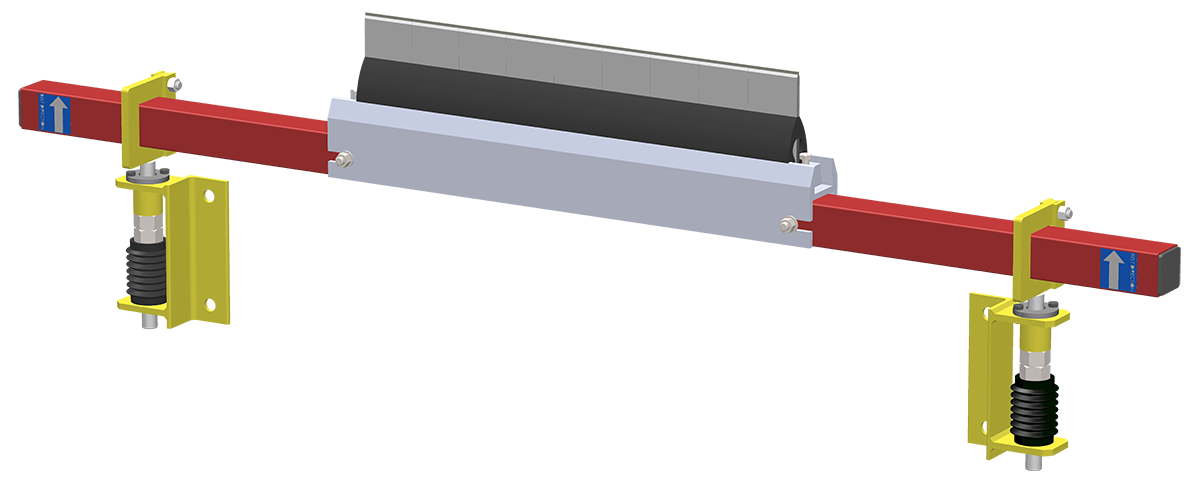

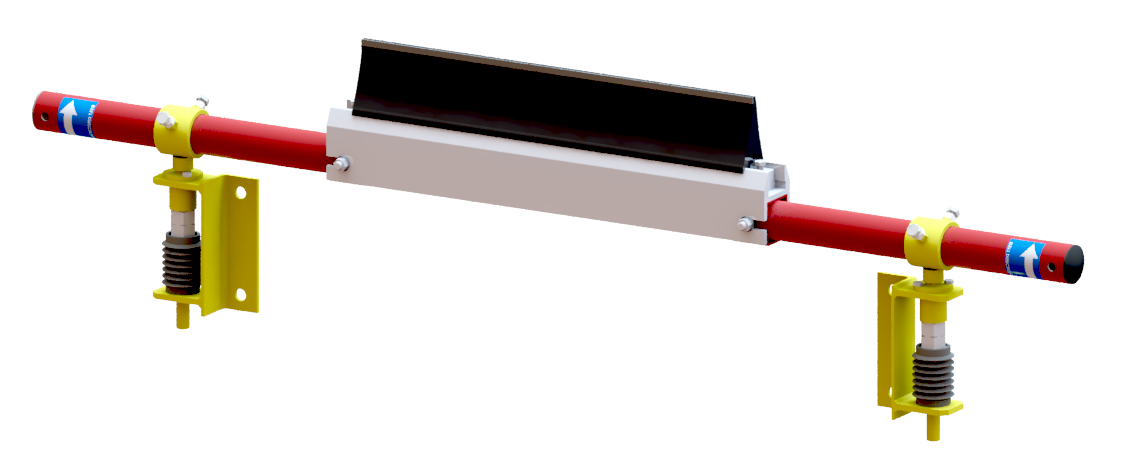

The JIMWAY Conveyor Spiral Return Roller is designed to keep conveyor belts clean, aligned, and efficient by automatically shedding material buildup on the return path. Its innovative spiral PU disc design creates a self-cleaning action that removes powder, fine granules, and sticky residues as the roller rotates. Built with precision-sealed bearings and triple labyrinth protection, it ensures smooth, low-friction operation even in dusty, abrasive, or wet conditions.

Manufactured with high-performance polyurethane discs and a non-stick shell surface, the Spiral Return Roller offers three times the lifespan of standard steel rollers. This makes it ideal for industries where carryback, belt contamination, and high maintenance costs are constant challenges.

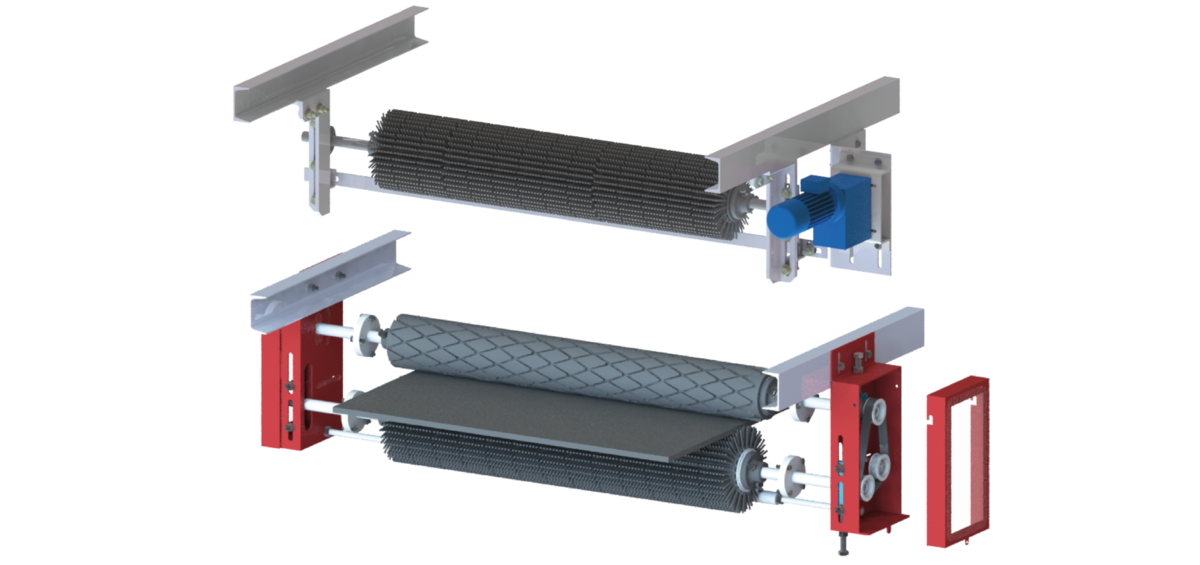

- High-Precision Bearings: Fitted with 6205–6306 2RS deep-groove ball bearings, ensuring smooth, low-noise operation under heavy-duty conditions.

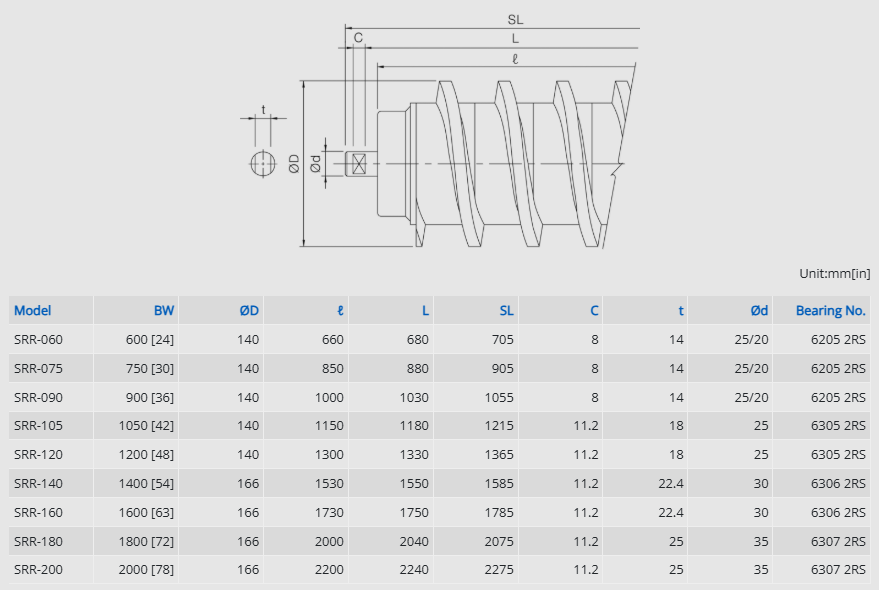

- Optimized Roller Design: Available in Ø140 and Ø166 mm (Ø5.5″ and Ø6.5″) diameters, customizable to suit specific conveyor configurations.

- Durable PU Discs:

- Constructed from high-quality polyurethane for superior resilience and flexibility.

- Effectively sheds powder and fine-grained materials, making it ideal for sticky or abrasive applications.

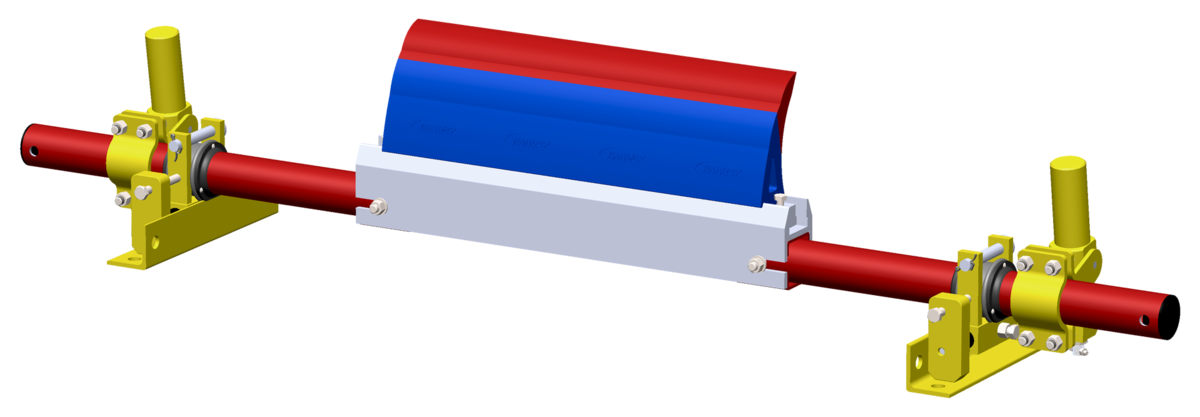

- Non-Stick Shell Surface:

- Prevents material accumulation and reduces carryback on belt surfaces.

- Cuts down on extra maintenance and cleanup costs.

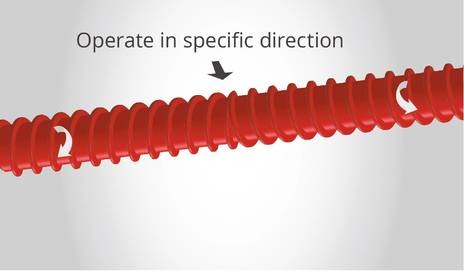

- Self-Cleaning Spiral Action:

- The unique outward rotation of the spiral discs continuously removes debris, keeping the belt surface clean during operation.

- Extended Service Life:

- Delivers up to three times the lifespan of conventional steel return rollers.

- Advanced Labyrinth Sealing:

- Triple labyrinth, non-contact seal design prevents dust and water ingress.

- Reduces roller drag, lowers energy consumption, and prolongs bearing life.

- Customizable Options:

- Sizes and configurations can be tailored to fit any belt width or system layout.

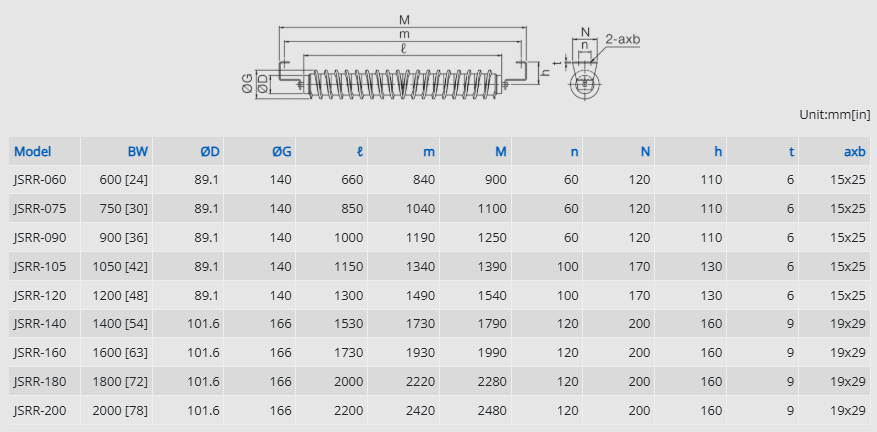

Specifications

Common Industries That Use This Product

Mining & Quarrying

Fertilizer & Chemical Processing

Recycling & Waste Management

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor