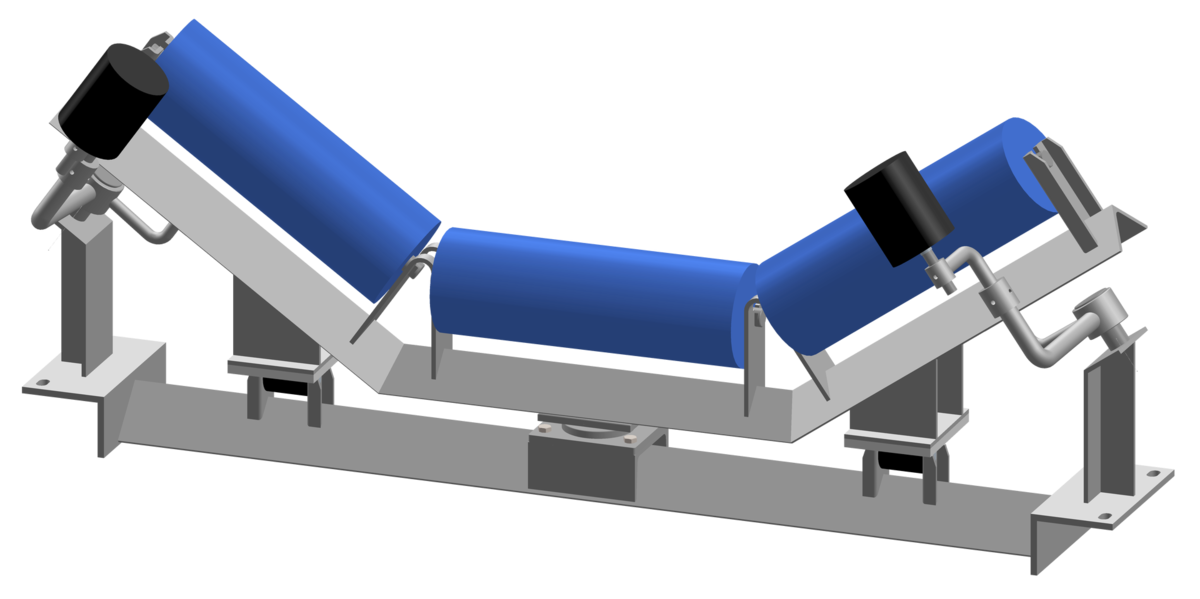

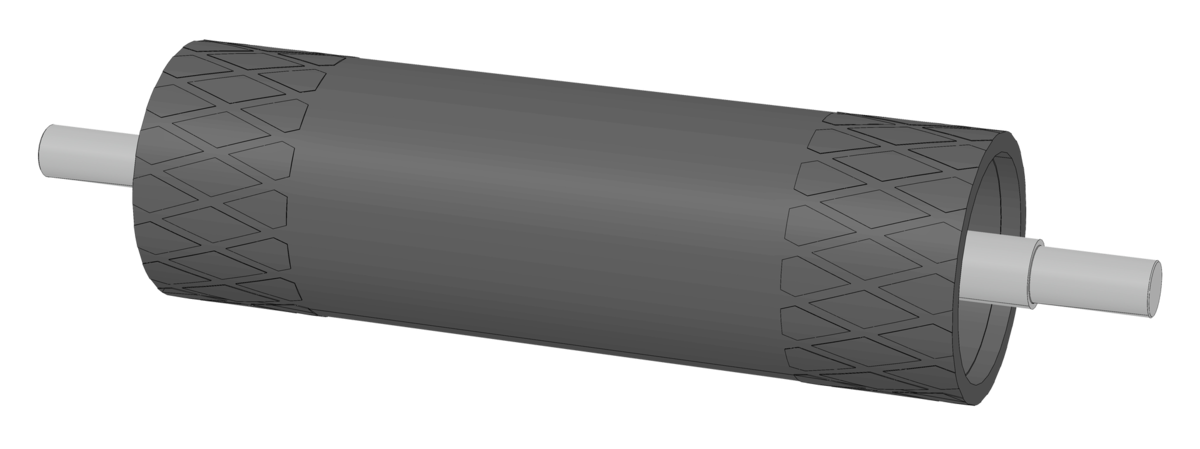

The JIMWAY Self-Training Idler is designed to automatically correct belt misalignment, ensuring stable tracking and smooth conveyor operation under all load conditions. Using a pivoting frame mechanism, it senses belt drift and guides the belt back to its proper position, preventing edge damage and structural wear. Suitable for both carry and return sides, the idler operates effectively on high-tension, heavy-load conveyors where consistent alignment is critical.

Engineered to meet JIS, CEMA, and DIN standards, the Self-Training Idler delivers reliable performance in demanding applications like mining, cement, and port terminals. It reduces downtime, minimizes spillage, and extends both belt and idler service life. This makes it a vital component for safe, efficient conveyor systems.

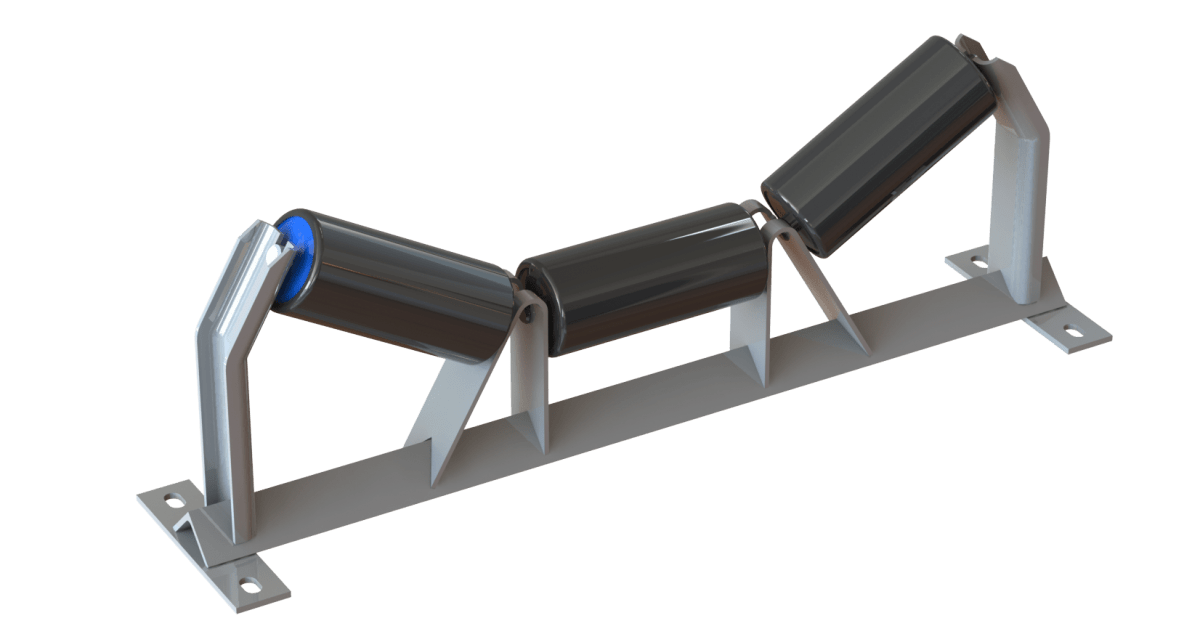

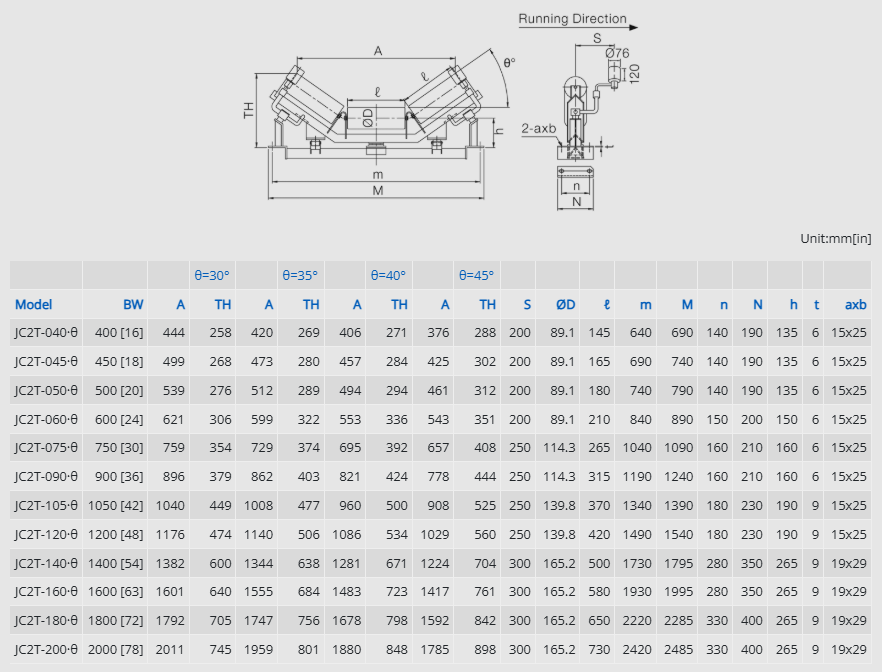

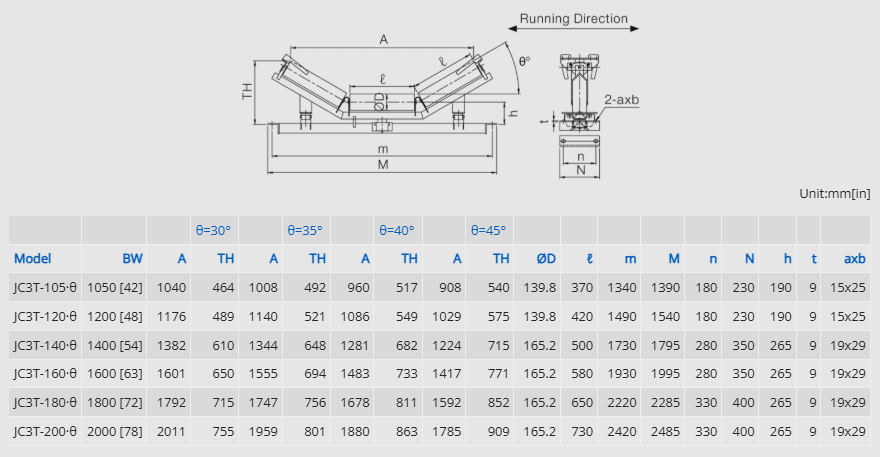

Carry Side Applications

- Position: Installed between general idlers, approximately 5 meters from the head/tail pulley or 15 meters apart in other locations.

- Trough Angles: Available in 25° to 45° configurations to suit various conveyor profiles.

- Belt Width Compatibility:

- JC2T Model: 400–2000 mm (16″–78″)

- JC3T Model: 1050–2000 mm (42″–78″)

- Ideal for high-load and high-speed conveyors that require precise belt tracking.

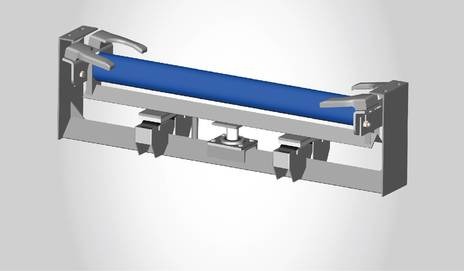

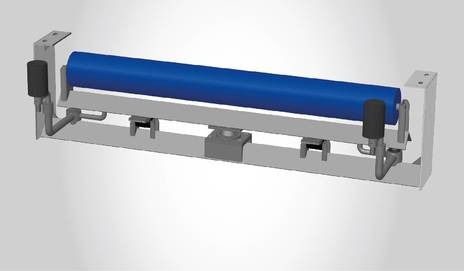

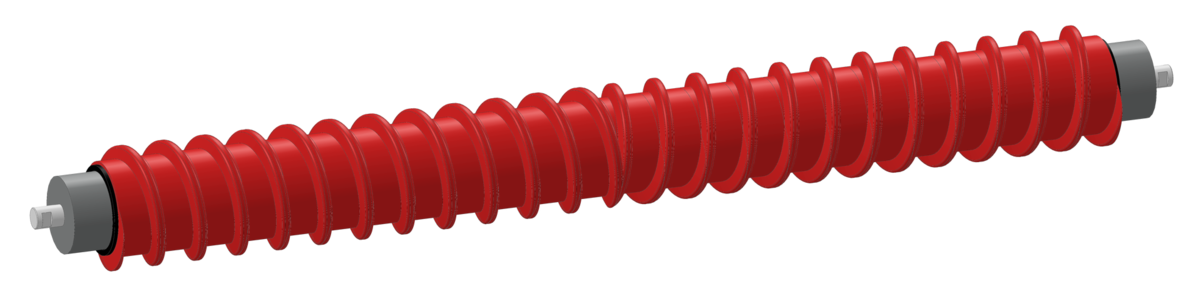

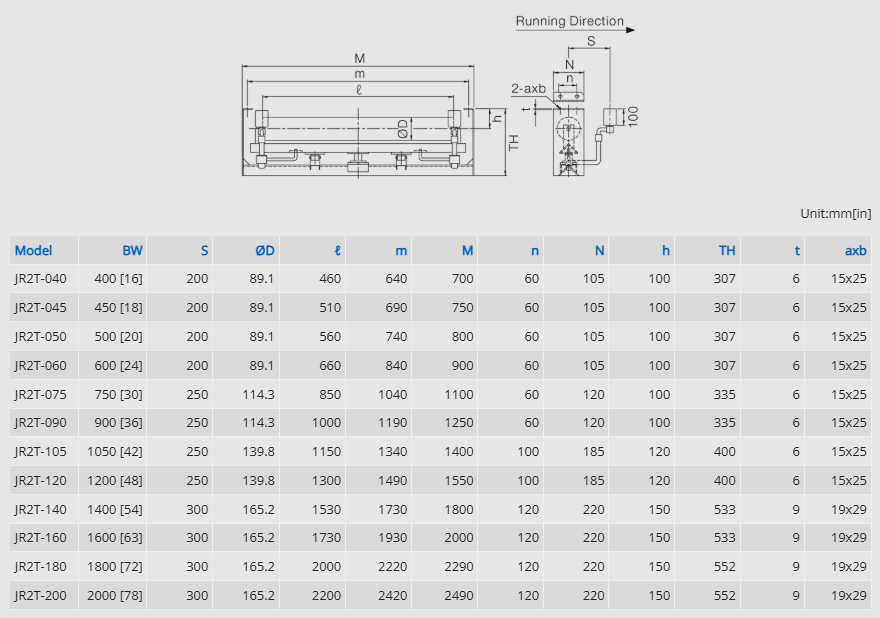

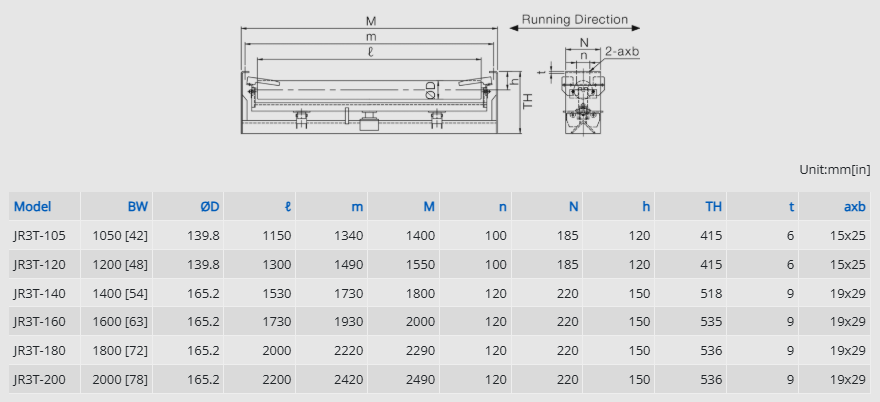

Return Side Applications

- Position: Installed between general idlers, typically spaced 15 meters apart along the return belt.

- Belt Width Compatibility:

- JR2T Model: 400–2000 mm (16″–78″)

- JR3T Model: 1050–2000 mm (42″–78″)

- Ensures consistent alignment on the return path, minimizing edge wear and belt drift.

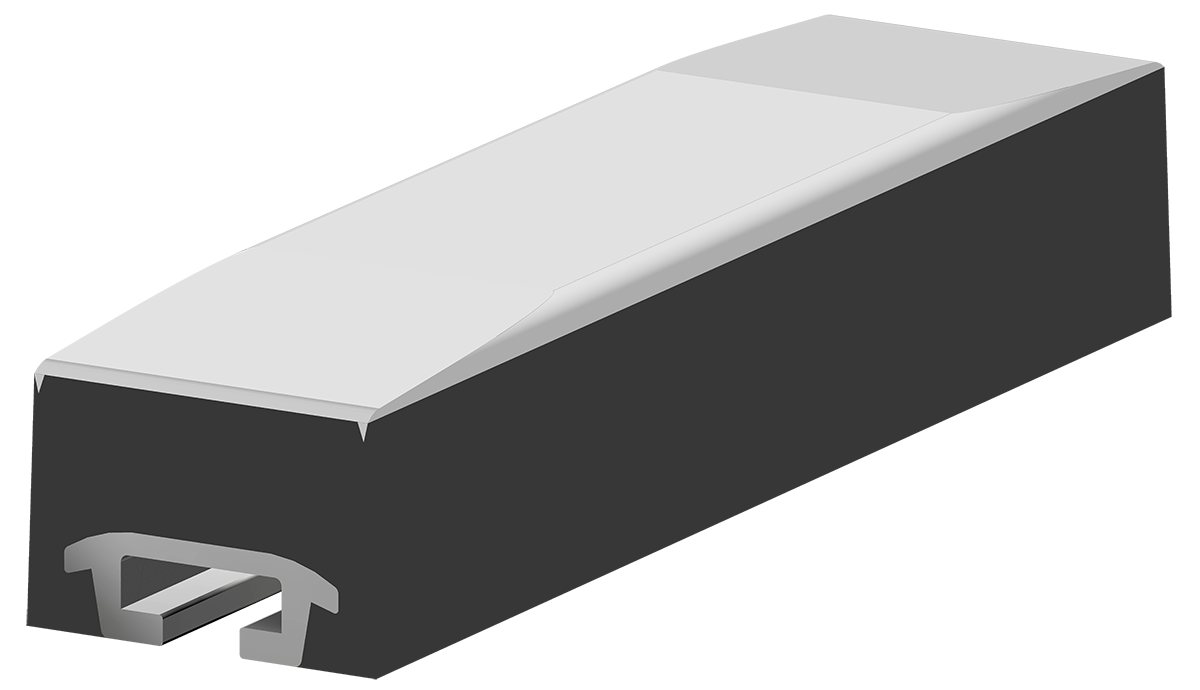

Performance Advantages

- Automatic Belt Correction: Continuously adjusts belt tracking to prevent drift and maintain centered operation.

- Prevents Damage: Protects both the belt and conveyor structure from excessive wear caused by misalignment.

- High-Load Capability: Designed for heavy-duty, high-tension conveyors, maintaining alignment under variable loading conditions.

- Extended Service Life: Reduces friction, spillage, and downtime, improving the overall efficiency and lifespan of the conveyor system.

Specifications

Common Industries That Use This Product

Steel & Metal Processing

Port & Bulk Terminals

Power Generation

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor