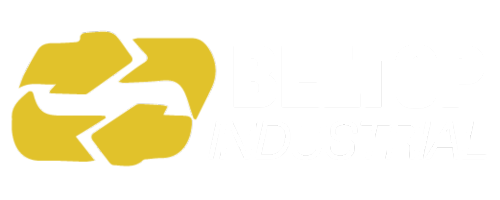

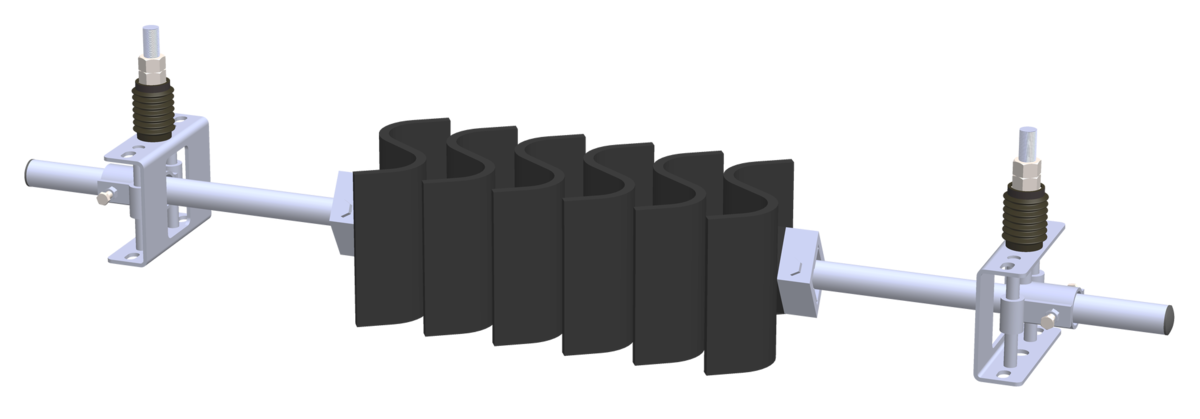

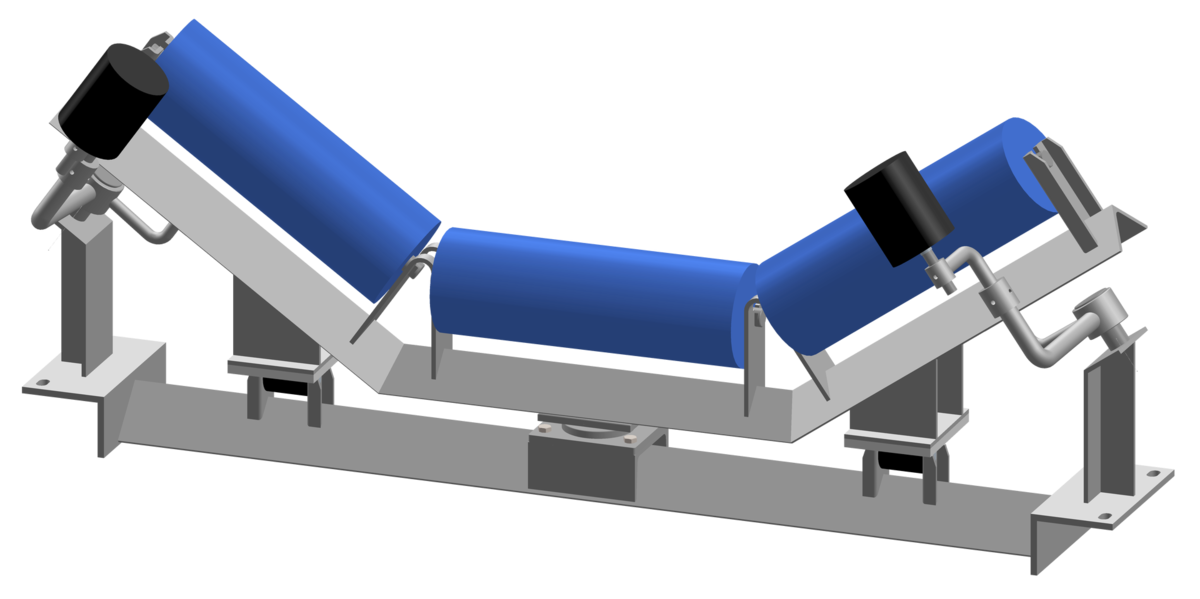

The JIMWAY Return Idler is engineered to support the return side of conveyor belts, ensuring stable belt alignment and smooth operation under all working conditions. Designed to prevent sagging and structural wear, it plays a key role in extending the life of both the belt and the conveyor frame. Available in steel or HDPE pipe options, it offers a balance of durability, weight reduction, and corrosion resistance to match different material handling environments.

Whether installed in mining, ports, cement, or recycling facilities, JIMWAY Return Idlers deliver reliable performance with minimal maintenance. Their precision engineering and choice of materials ensure quiet operation, easy installation, and long-term efficiency across demanding industrial applications.

General Information

- Position: Installed on the return side of the conveyor to support the unloaded belt.

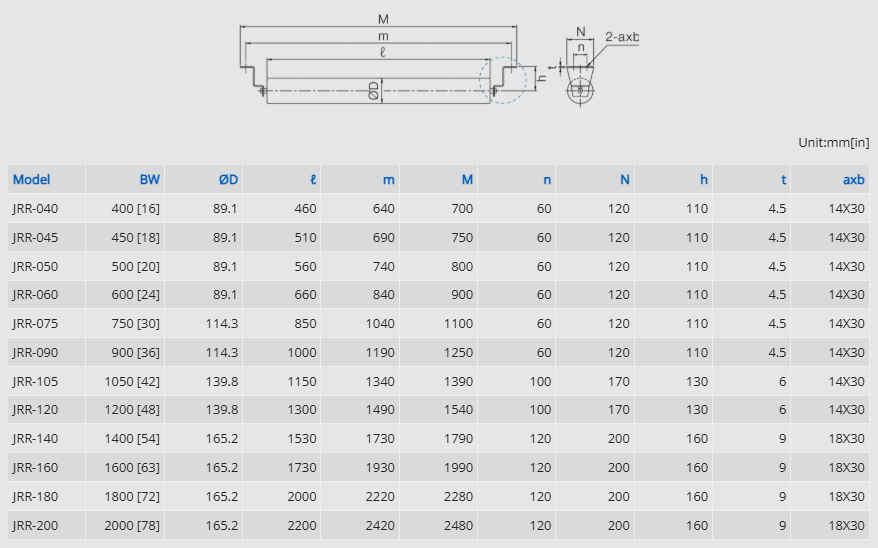

- Belt Width Range: Compatible with 400–2000 mm (16″–78″) belt widths.

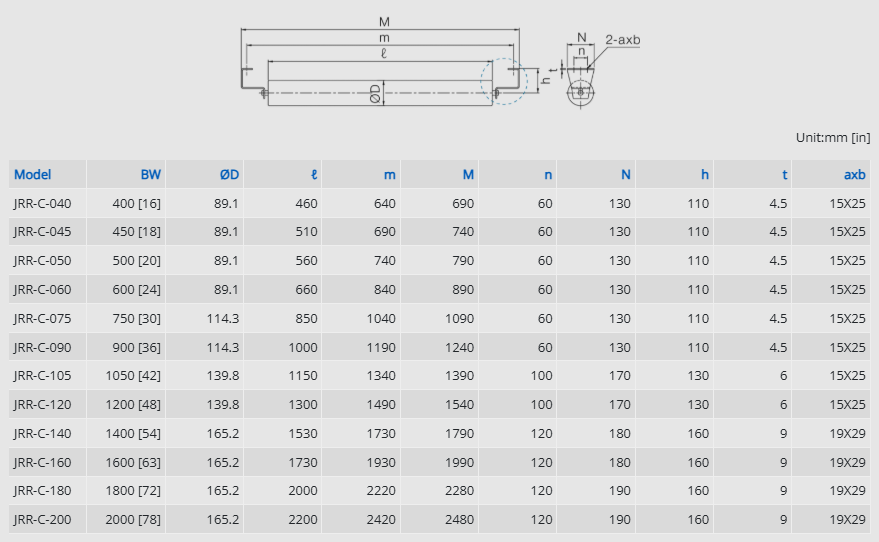

- Optional Model (JRR-C): Includes reinforced construction for preventing structural damage under heavy loads.

HDPE Pipe

- In-House Production: Manufactured using JIMWAY’s own HDPE pipe extrusion technology for consistent quality.

- Lightweight & Safe Handling: Up to 50% lighter than steel, reducing transport and installation costs.

- Corrosion & Chemical Resistance: Ideal for humid, wet, or corrosive environments, ensuring long-term durability.

- Low Noise Operation: Quiet performance makes it suitable for enclosed or noise-sensitive areas.

- Non-Toxic & Belt Friendly: Smooth surface prevents belt wear and contamination during operation.

- Energy Efficient: Lightweight construction lowers rotational resistance, reducing energy consumption.

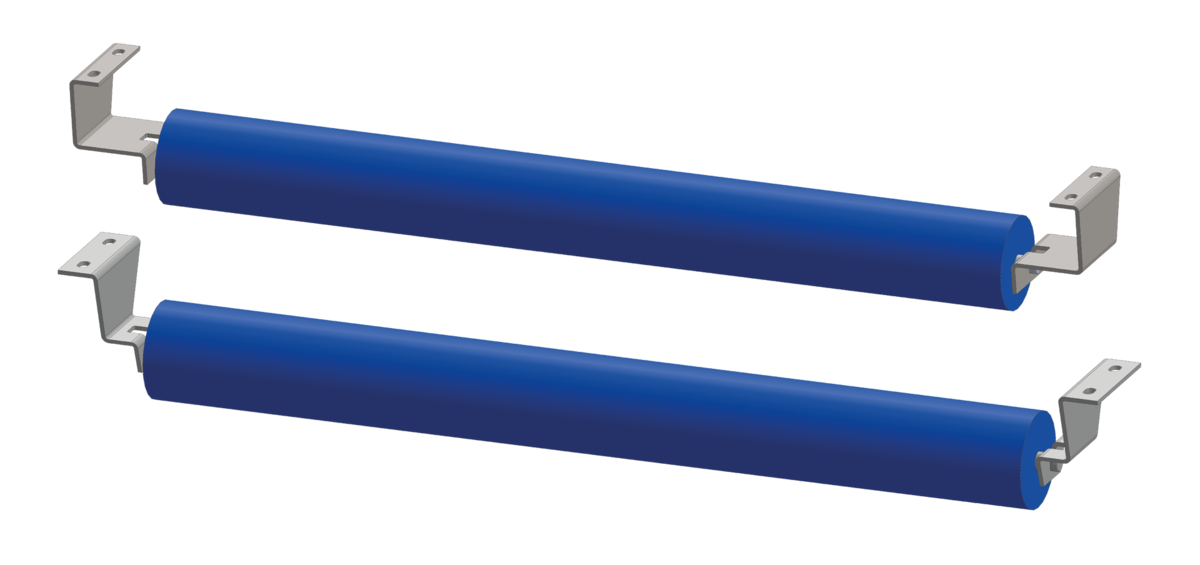

Steel Pipe

- Heavy-Duty Construction: Designed for high-load and continuous operation in rugged industrial environments.

- Powder-Coated Surface: Provides superior rust and corrosion protection, even in outdoor applications.

- Long Service Life: Rigid structure and protective coating extend lifespan and reduce maintenance intervals.

- Consistent Belt Support: Maintains belt stability and protects conveyor structures from wear and misalignment.

Specifications

Common Industries That Use This Product

Food Processing & Packaging

Pulp & Paper Industry

Grain & Agricultural Handling

Fertilizer & Chemical Processing

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor