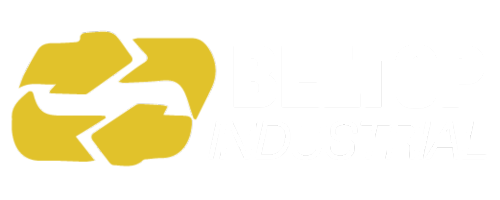

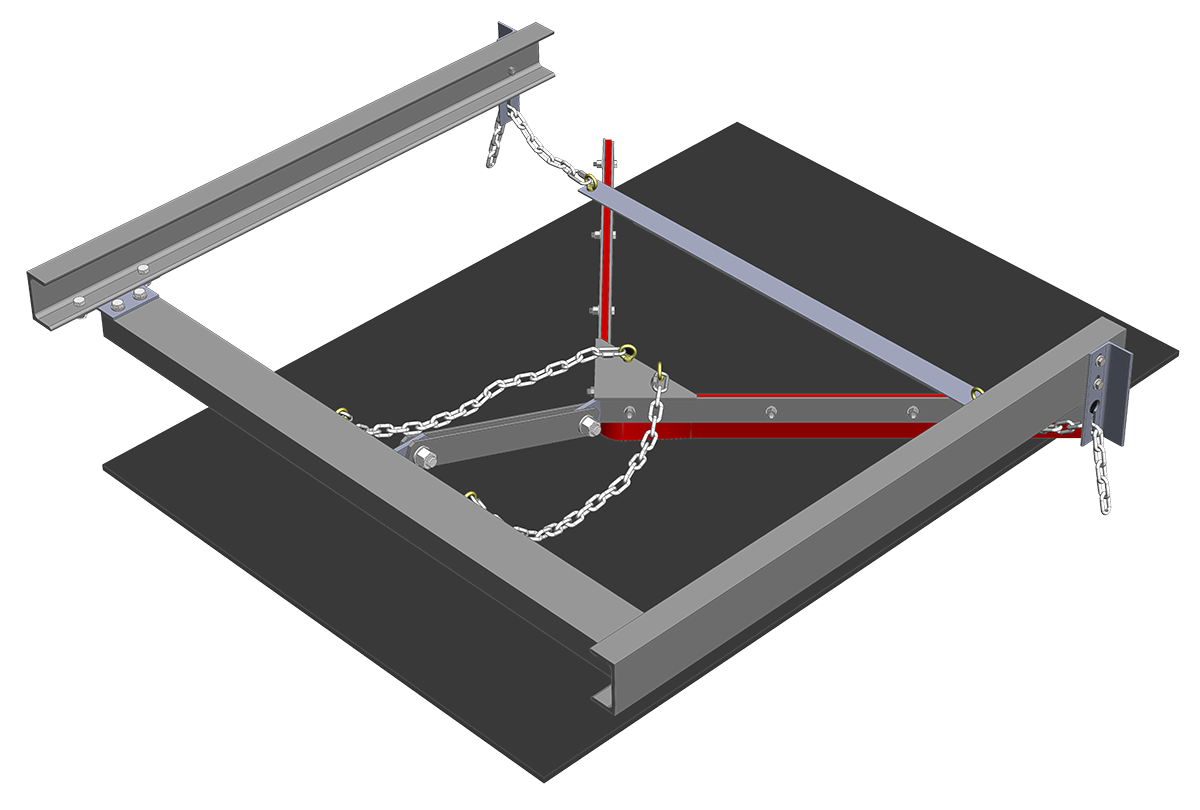

The JIMWAY Impact Bed provides complete belt support and superior shock absorption at conveyor loading zones, minimizing damage and spillage caused by heavy material impact. Built with adjustable trough angles and high-performance impact bars, it ensures full contact with the belt, reducing vibration and preventing sagging. The system replaces traditional roller setups with a stable, low-friction surface that prolongs belt life and improves sealing efficiency at transfer points.

Designed for high-impact applications, the JIMWAY Impact Bed combines durability, ease of maintenance, and safety. Its modular frame allows quick bar replacement without lifting the belt, reducing downtime and improving operational productivity in demanding bulk-handling environments.

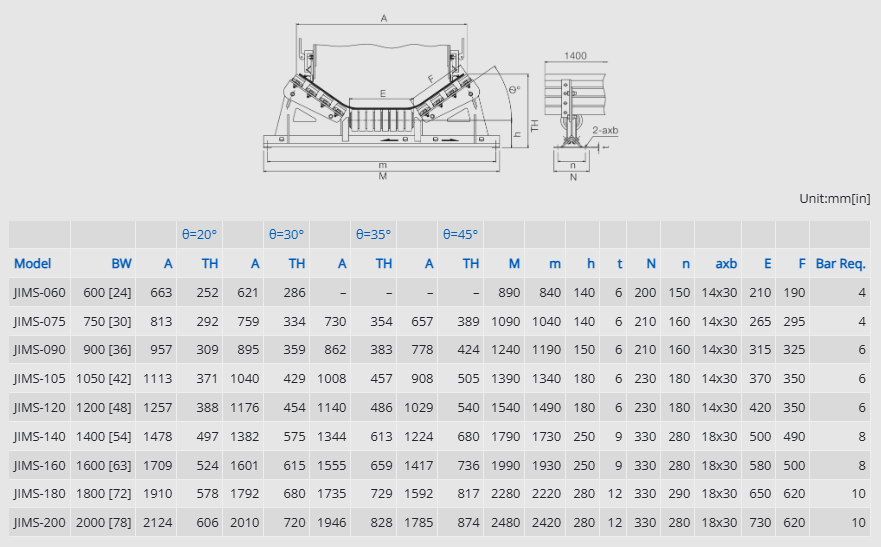

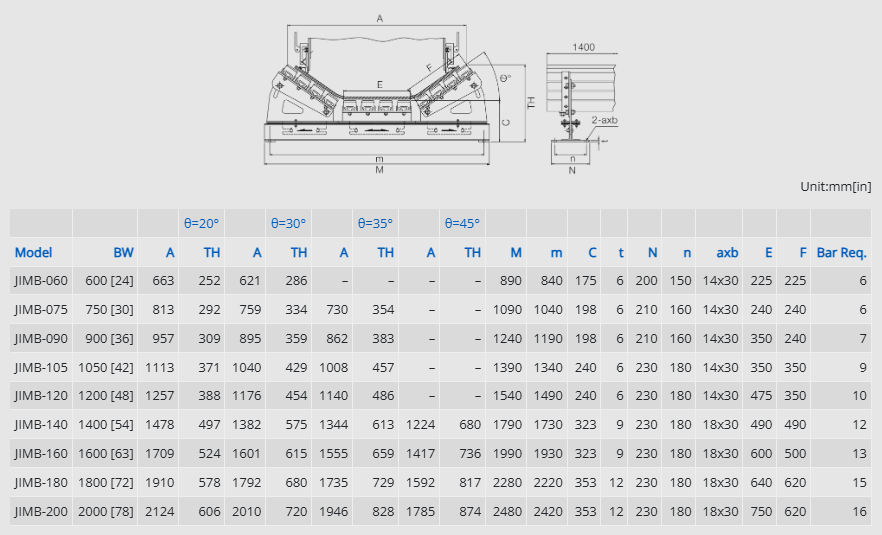

- Belt Width Compatibility: Suitable for conveyors 600–2000 mm (24″–78″) wide.

- Adjustable Trough Angles: Configurable at 20°, 30°, 35°, or 45°, allowing precise belt support for various materials and load conditions.

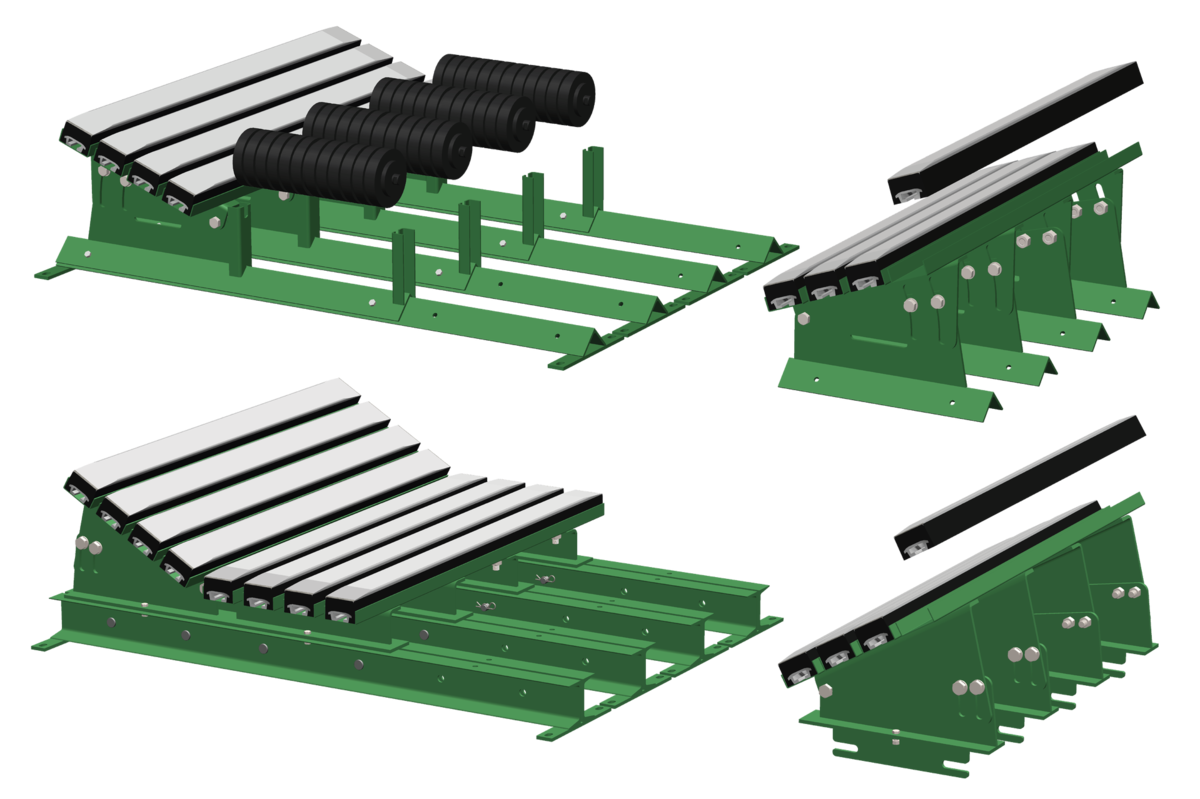

- Spill & Leak Control:

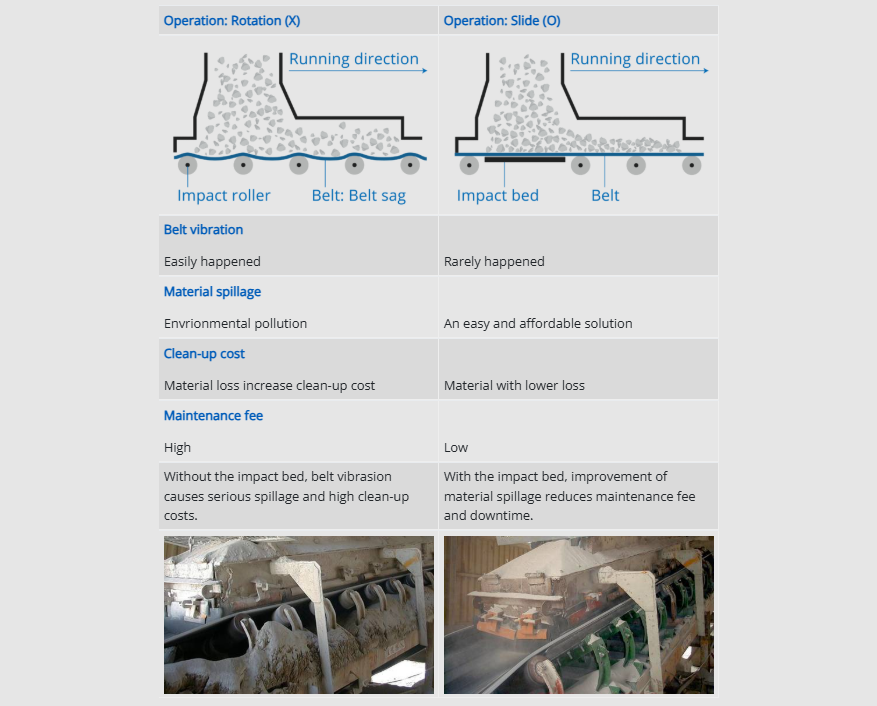

- Minimizes belt vibration and impact shock for smooth operation.

- Adjustable frame ensures complete contact between the belt and impact bars, preventing sagging and spillage.

- Reduced Downtime:

- Quick-change bars and rollers can be replaced without raising the belt.

- Easy slide-out design enhances safety and simplifies maintenance in confined spaces.

- Belt-Friendly Design:

- Provides stable, continuous support under the loading zone to prevent belt damage and edge wear.

- Low-friction surface minimizes heat and stress on the belt during operation.

- Durable & Modular Construction:

- Heavy-duty frame and impact bars ensure long service life in high-impact applications.

- Modular assembly allows customization for conveyor width and material flow requirements.

Principle of Operation

Specifications

Common Industries That Use This Product

Power Generation & Biomass Handling

Fertilizer & Chemical Processing

Airport Cargo & Logistics Systems

Construction & Building Materials

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor