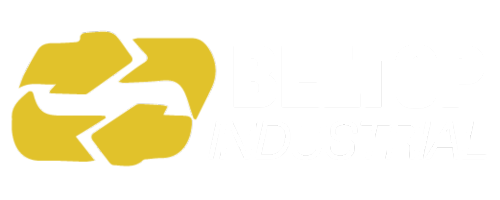

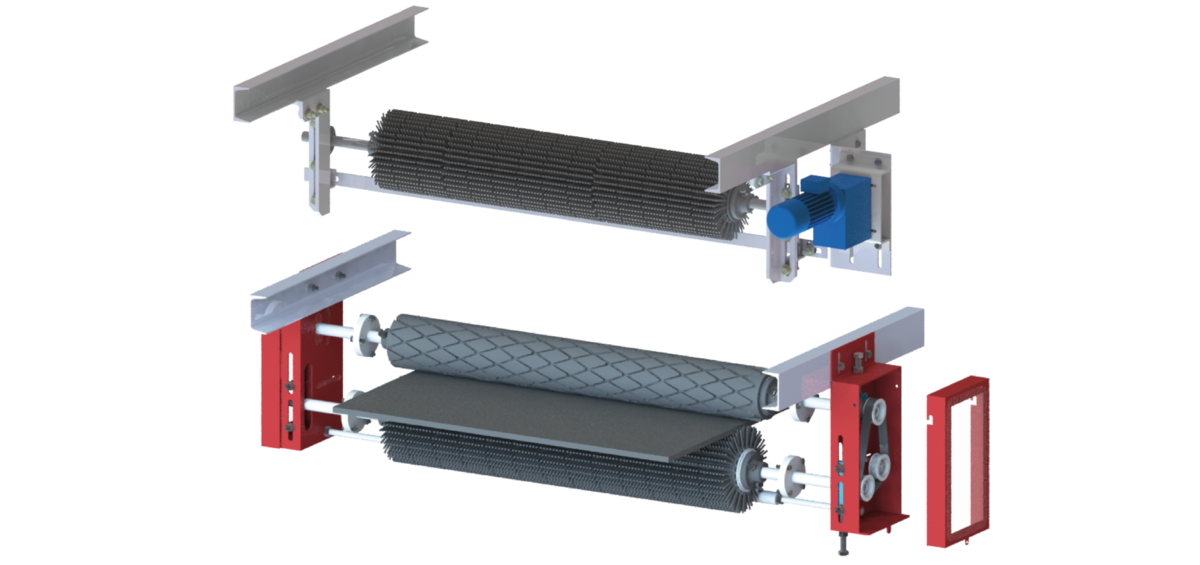

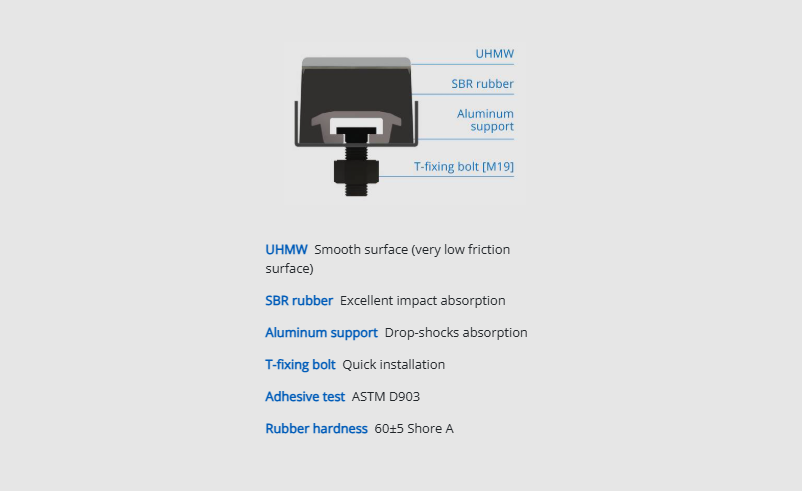

The JIMWAY Impact Bar is designed to absorb the force of falling materials at conveyor loading points, protecting belts from impact damage and reducing maintenance downtime. Constructed with a high-impact rubber core and a low-friction UHMW (Ultra High Molecular Weight) polyethylene surface, it provides exceptional energy absorption while allowing the belt to glide smoothly over the bar without wear or drag.

With easy T-bolt installation and modular length options, JIMWAY Impact Bars deliver reliable performance in high-load environments such as mining, cement, and bulk handling facilities. They help eliminate belt sag, reduce spillage, and extend the lifespan of both the belt and the conveyor structure.

- Available Dimensions:

- Width (W): 100 mm

- Height (H): 75 mm

- Length (L): 1250 / 1400 / 1500 / 1600 mm (customizable)

- Ultra-Low Coefficient UHMW Surface:

- Provides a smooth, low-friction gliding surface for the belt.

- Offers longer wear life and reduces drag on the belt surface.

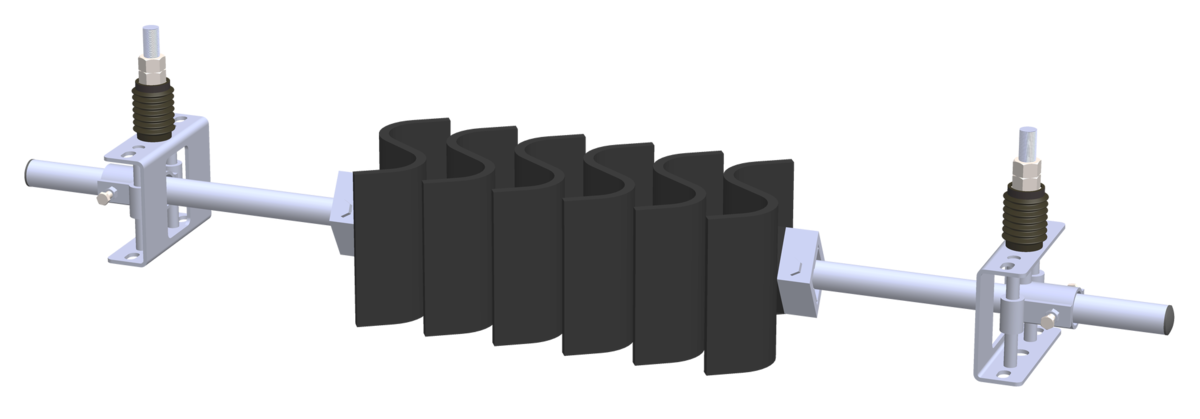

- Prevents Belt Mistracking & Sagging:

- Stabilizes the belt at impact zones, minimizing vibration and belt bounce.

- Reduces spills, leaks, and material loss along the loading point.

- Gentle on the belt, ensuring extended operational life.

- Absorbs high-impact energy to protect belt and structure integrity.

- Quick Installation:

- Features T-fixing bolts for fast and secure mounting.

- Simplifies maintenance and replacement, minimizing system downtime.

- Durable Construction:

- Combines a tough rubber impact core with a wear-resistant UHMW top for superior performance in abrasive, high-impact conditions.

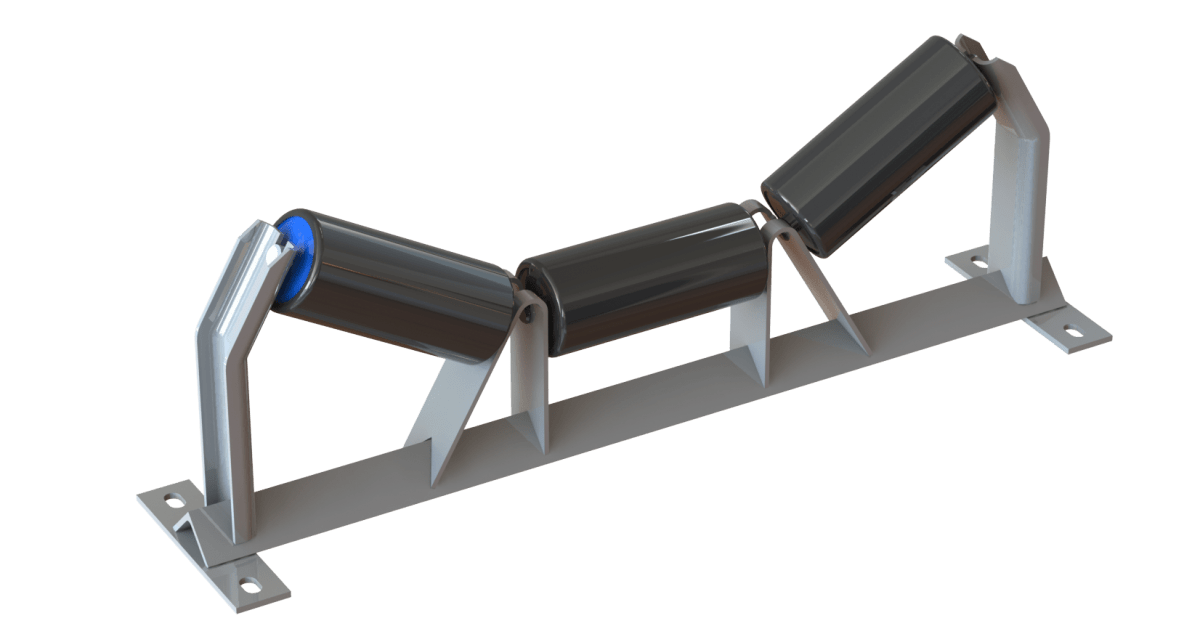

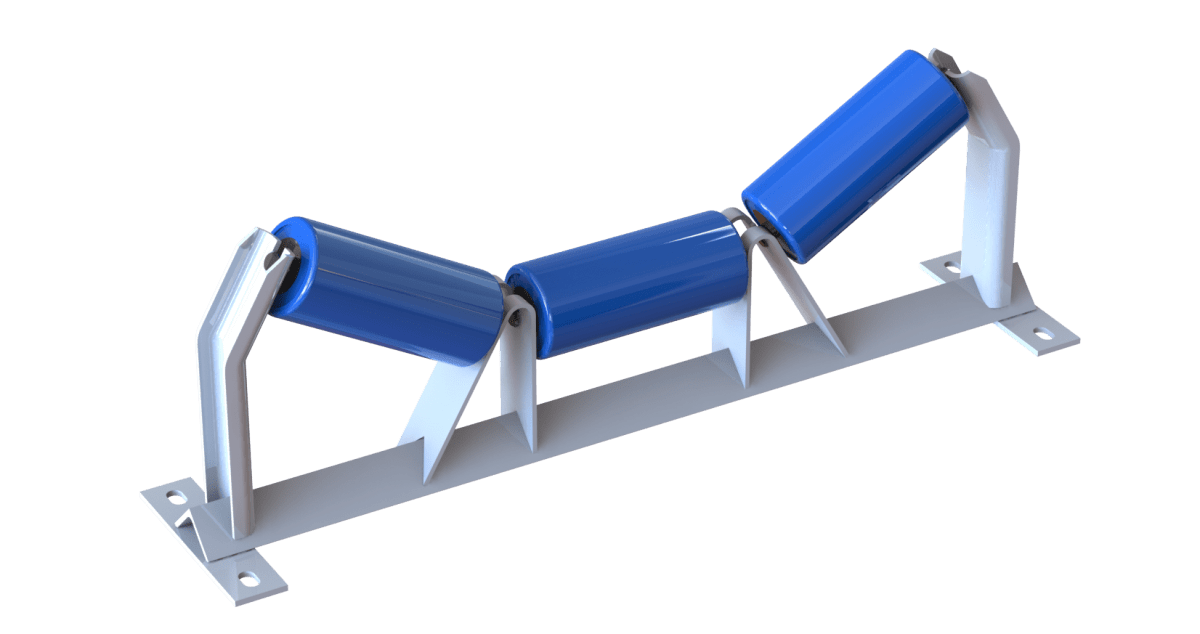

Product Components

Common Industries That Use This Product

Construction & Building Materials

Steel & Metal Fabrication

Cement & Aggregate Production

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor