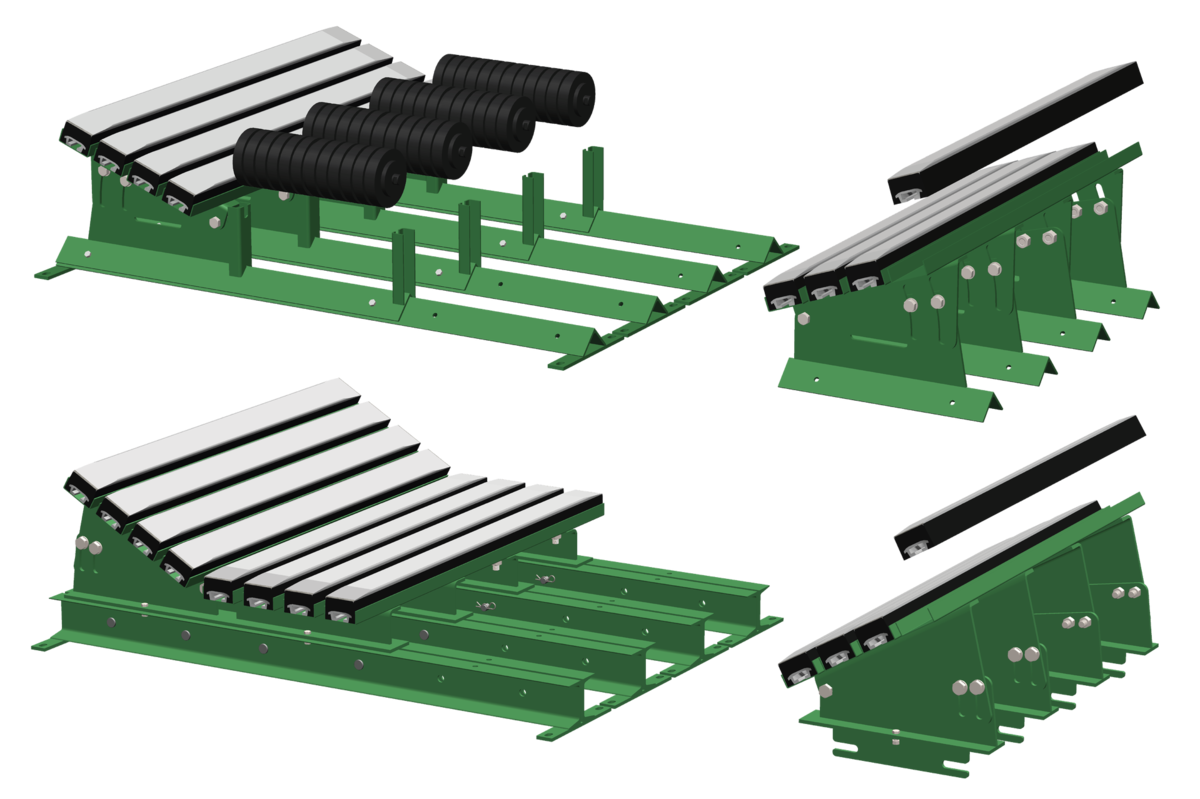

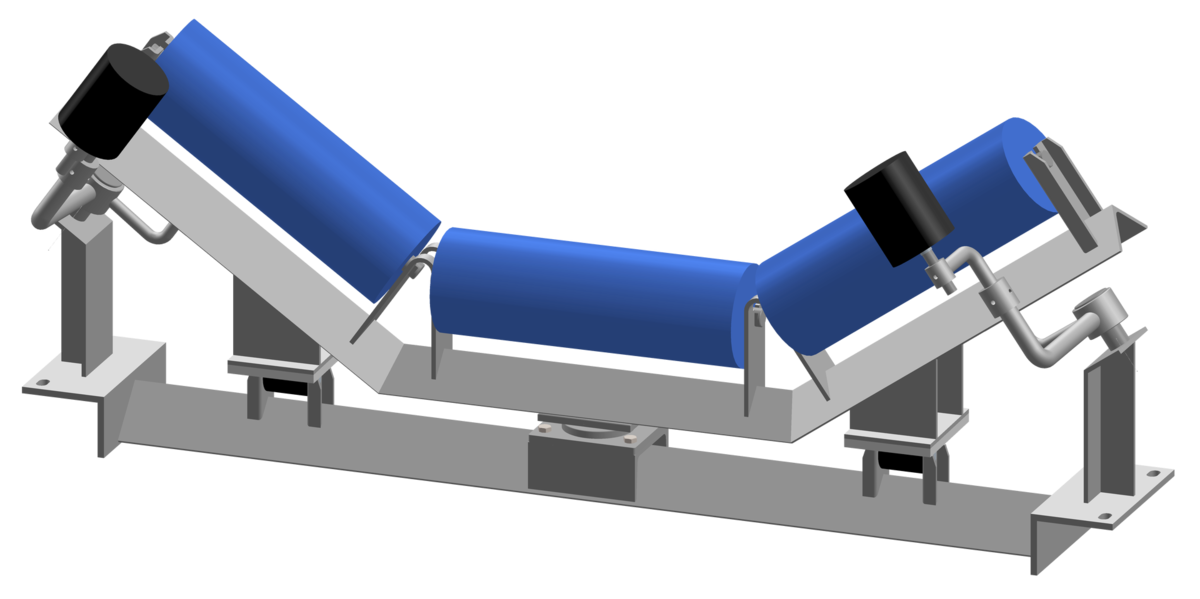

The JIMWAY 3D Tracker Roller is a self-aligning solution engineered to keep conveyor belts perfectly centered, reducing spillage, belt wear, and unplanned downtime. Its innovative 3D tracking system responds automatically to belt misalignment by applying a gentle, controlled steering force that re-centers the belt without damage or interruption.

Built with precision bearings, heavy-duty steel construction, and corrosion-resistant components, the 3D Tracker Roller performs reliably in even the harshest field conditions. Whether installed on load-carrying or return sides, it ensures stable tracking, smoother material flow, and longer belt life. It is an essential upgrade for conveyors in high-capacity, heavy-impact operations.

Highly Effective Tracking Action

- Quick Correction: Automatically and quickly adjusts any belt misalignment, keeping the conveyor centered and running smoothly.

- Prevents Damage: Protects the belt and conveyor structure from wear, tearing, or edge fraying caused by continuous drift.

- Reduces Spillage: Maintains proper tracking to prevent material loss along the sides of the belt, improving cleanliness and safety.

- Minimizes Downtime: Fewer belt-related stoppages mean more uptime and direct cost savings for the operation.

- Extends Service Life: Proper alignment reduces stress on mechanical components, extending the overall life of the conveyor system.

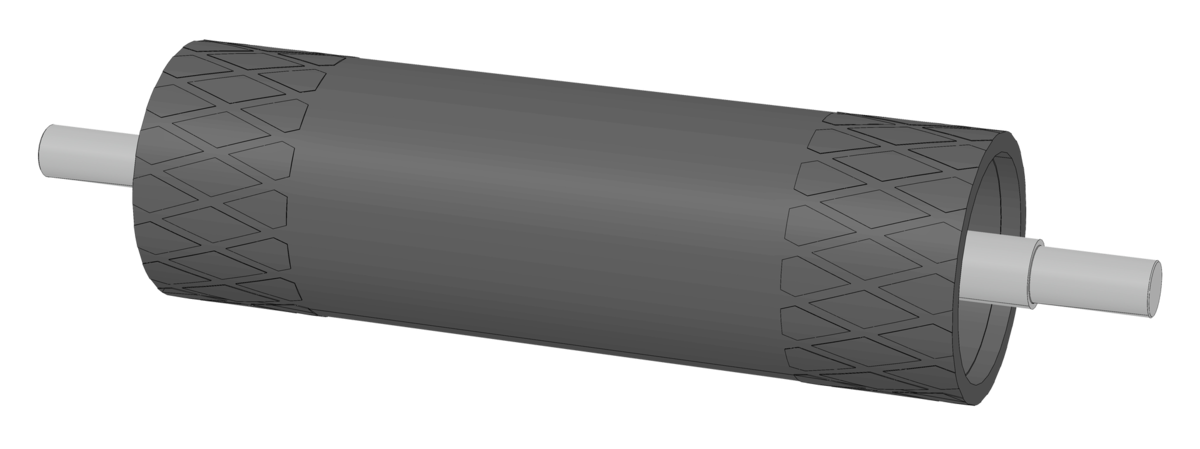

Diamond-Grooved Top Surface

- Self-Cleaning Design: The diamond-grooved surface continuously sheds dirt, water, and buildup, keeping the roller surface clean during operation.

- Water & Residue Shedding: Effectively channels moisture and debris away from the belt, reducing slippage and buildup in wet or dusty environments.

- Enhanced Traction: Provides a firm grip between the belt and roller, improving traction and stability even under heavy loads or fluctuating speeds.

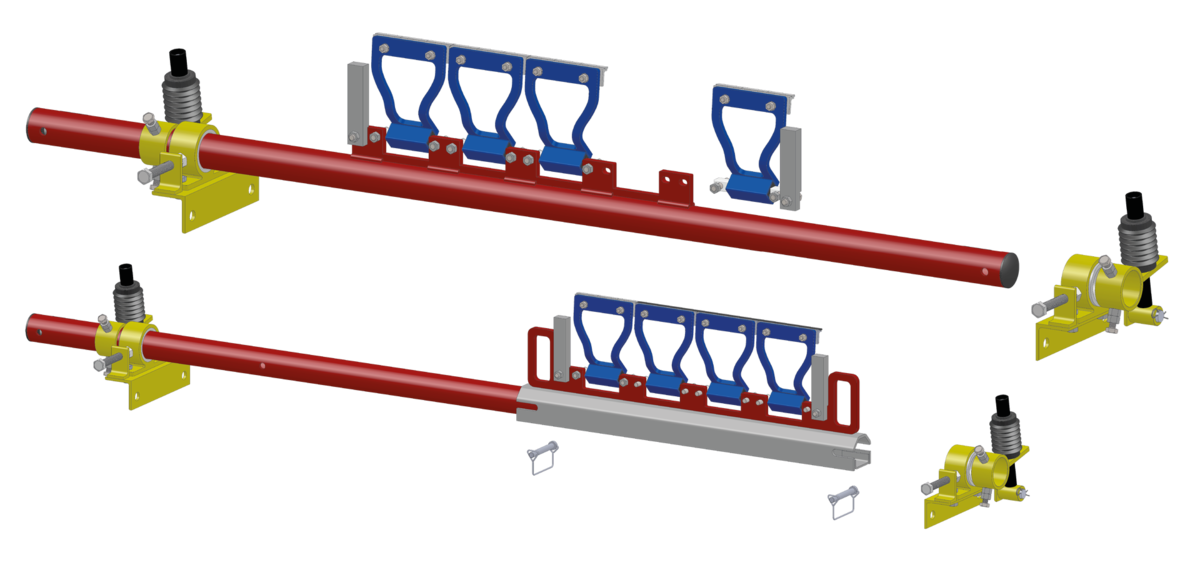

Principle of Operations

Belt normal operation

Belt right deviation

Specifications

Common Industries That Use This Product

Mining & Quarrying

Shipping Ports

Power Generation

Recycling & Waste Handling

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor