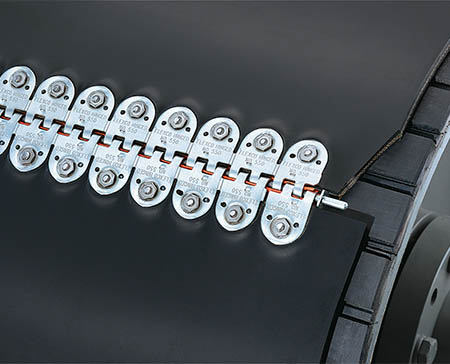

The Flexco® Bolt Hinged Fastening System is engineered for tough, high-tension conveyor applications where belts experience frequent impact, heavy loads, or abrasive conditions. Its robust, hinged design allows the belt to flex around pulleys and troughing idlers while maintaining a secure, long-lasting splice.

Bolts pass through the belt to provide a solid, mechanical connection that won’t slip or pull out, even under extreme tension. The system’s flexibility makes it ideal for belts that require frequent maintenance, cleaning, or length adjustments. With proven durability and simple installation, the Flexco® Bolt Hinged Fastening System helps keep operations running efficiently, minimizing costly downtime.

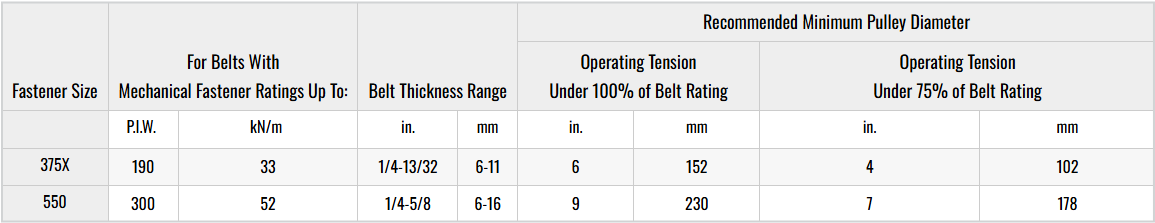

- High Strength Rating: Handles loads from 190 to 300 PIW (33–52 kN/m), providing exceptional splice strength for heavy-duty conveyor applications.

- Belt Compatibility: Suitable for belts 1/4” to 5/8” (6 mm to 16 mm) thick, making it ideal for tough, high-tension operations.

- Pulley Range: Designed for pulley diameters from 6” to 9” (150 mm to 225 mm), ensuring smooth flexing and long-lasting splice performance.

- Hinged Design: The bolt-hinged construction allows for belt flexibility and quick maintenance. Perfect for systems using smaller pulleys or mechanical take-ups.

- Quick Separation: The splice can be easily separated by removing the hinge pin, simplifying belt cleaning, repair, or replacement.

- Secure Grip: Specially formed teeth penetrate the belt carcass to maximize holding strength without damaging internal fibers.

- Easy Installation: Piloted bolts guide each fastener into place for fast, accurate assembly, reducing setup time in the field.

- Accurate Alignment: A curved templet ensures precise bolt-hole placement and even tension across the entire belt width, promoting longer splice life.

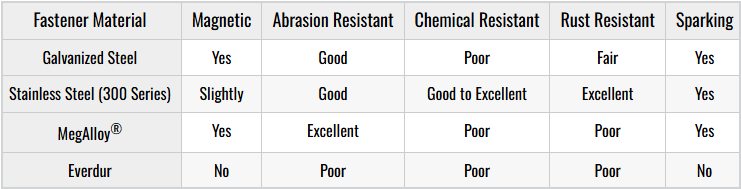

- Durable Construction: Built to perform under impact, abrasion, and harsh environments, maintaining reliable splice integrity over time.

Specifications

Common Industries That Use This Product

Mining

Aggregate & Cement Production

Forestry & Lumber Processing

Steel & Metal Processing

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor