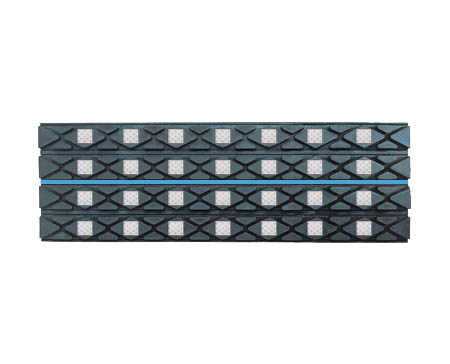

The Flex-Lag® Diamond Pattern Rubber Lagging is engineered to enhance conveyor performance by improving friction between the belt and pulley. Its diamond-shaped grooved surface channels away water, dirt, and debris, ensuring consistent belt contact and reducing slippage in both wet and dry conditions.

Built with a durable rubber compound, this lagging protects pulley surfaces from wear and extends belt life by minimizing tension loss and misalignment. Ideal for both drive and non-drive pulleys, the Diamond Pattern Lagging offers a reliable, cost-effective solution for general-purpose material handling operations.

- Enhanced Grip: Features 15% ceramic tile coverage, combining the strength of ceramic with the flexibility of rubber for improved belt traction.

- Superior Friction: The large ceramic tiles are molded directly into the diamond-shaped rubber surface, significantly increasing the coefficient of friction compared to standard Diamond Pattern Rubber Lagging.

- Efficient Water Shedding: The bidirectional groove design channels away water and debris from both directions, ensuring stable performance in wet or variable conditions.

- Cost-Effective Performance: Offers many of the advantages of a full ceramic product — including added grip and wear resistance — at a more affordable price, making it ideal for light to medium-duty applications.

- Certified Safety: Available with FRAS-approved rubber, marked in blue for easy on-site identification and compliance with fire-resistant and anti-static standards.

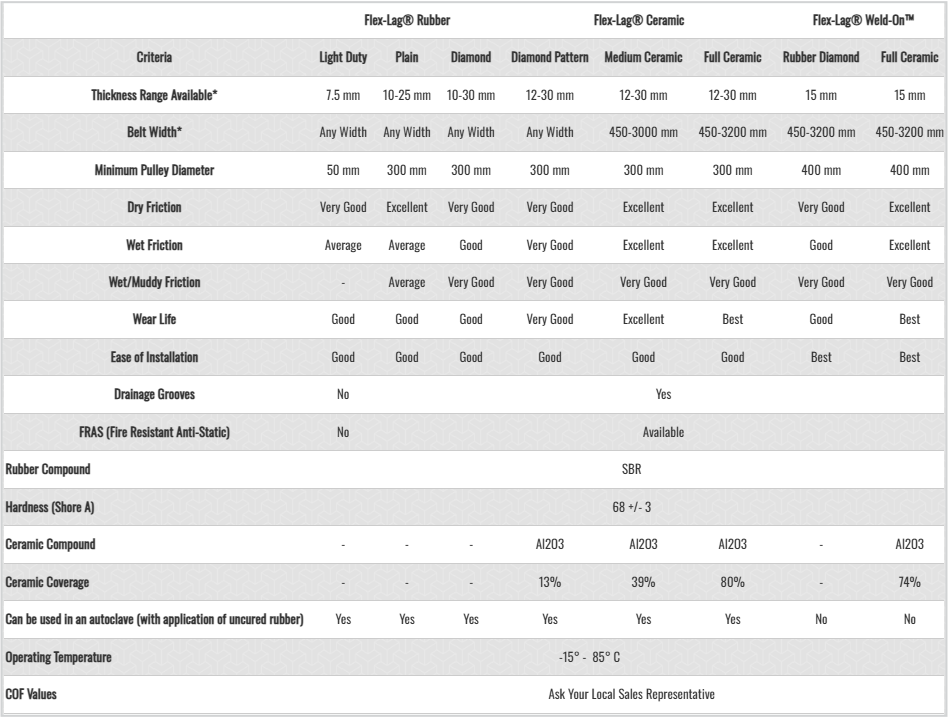

Specifications

- Minimum Pulley Diameter: 12″ (300 mm)

- Lagging Thickness: 0.5″ to 1.15″ (12 mm to 30 mm)

- Temperature Rating: 5°F to 185°F (-15°C to 85°C)

- Rubber Compound: SBR (Styrene-Butadiene Rubber)

- Rubber Hardness: 68 ± 3 Shore A

- FRAS Certification: Fire Resistant and Anti-Static (MSHA Certification No. IC-190)

- Ceramic Material: Aluminum Oxide (Al₂O₃)

- Ceramic Hardness: 83 HRA (Rockwell Hardness Scale A)

- Roll Dimensions:

- Width: 8″ (200 mm)

- Length: 21 ft. (6.5 m)

To select the right pulley lagging, be sure to consider the environmental conditions around the pulley:

- Belt condition, i.e., wet or dry

- The service required for bonded lagging versus weld-on

- The expected wear life of the lagging

*Additional thicknesses and widths available as special orders.

Installations

Installing Flex-Lag® Diamond Ceramic Lagging is fast, efficient, and does not require removing the pulley from the conveyor system.

- Determine Lagging Quantity: Use the Flexco Lagging Calculator to determine the exact number of rolls or strips needed for your pulley size.

- Surface Preparation: Clean and roughen the pulley surface to ensure strong adhesion.

- Apply Adhesive: Use Flex-Lag® Cold Vulcanizing Adhesive to bond the lagging directly to the pulley.

- Mount Lagging: Align the strips evenly and press firmly for full surface contact, removing any trapped air.

- Curing: Allow sufficient curing time before resuming conveyor operation.

This cold-bonding process saves labor, reduces downtime, and allows on-site installation — providing a durable, high-traction solution that’s ready to perform immediately.

Common Industries That Use This Product

Power Generation

Cement & Concrete Production

Fertilizer & Chemical Processing

Why Choose Beltop

With over 30 years of industry experience, Beltop Industrial has earned a trusted reputation as a leading distributor of industrial conveyor belts, power transmission belts, and mechanical belt fasteners.

Trusted Industry Experience

With over 30 years of experience, Beltop Industrial is a trusted name in delivering reliable, high-performance belting solutions across industries.

Industry-Wide Expertise

We supply conveyor and transmission belts to a wide range of industries, ensuring smooth operations from manufacturing to logistics.

Quality and Precision

We combine top-tier sourcing with technical know-how to provide superior belting solutions that meet the highest industry standards.

Customer-First

We prioritize our customers by offering tailored solutions and dedicated support to keep your business running at full capacity.

Extensive Supplier Network

Our strong global network of suppliers allows us to deliver quality products efficiently and cost-effectively.

Future-Focused & Adaptive

Continuously evolving, we stay ahead of market trends to provide innovative, future-ready belt solutions.

Request for Quote

Contact us by submitting the contact us form, and our team will reach out to you shortly.

- enquiry@beltop.com.my

- +603-8060 6883

- 33, Jalan BP 5/5, Bandar Bukit Puchong, 47120 Puchong, Selangor